Priming and disinfection are very ‘close-related’ Seed Enhancement Techniques.

Mostly seeds are wetted in a liquid-solid-vapor-matrix when primed and only ‘dry-heat’ disinfection does not wet the seed.

So in the section you will see equipment with multi-purpose, targeted priming and/or disinfection modules.

During the last few years this product group has enjoyed a lot of attention.

Mechanisation- and automation allowed now allows for higher volume seeds to be consistently treated. This can encompass priming and/or disinfection.

The disinfection of seeds for agriculture and horticulture is important to grow good plants, either at the plant raiser’s greenhouse or in the field. Due to the drastic limitation of registered seed applied fungicides alternatives have to be available.

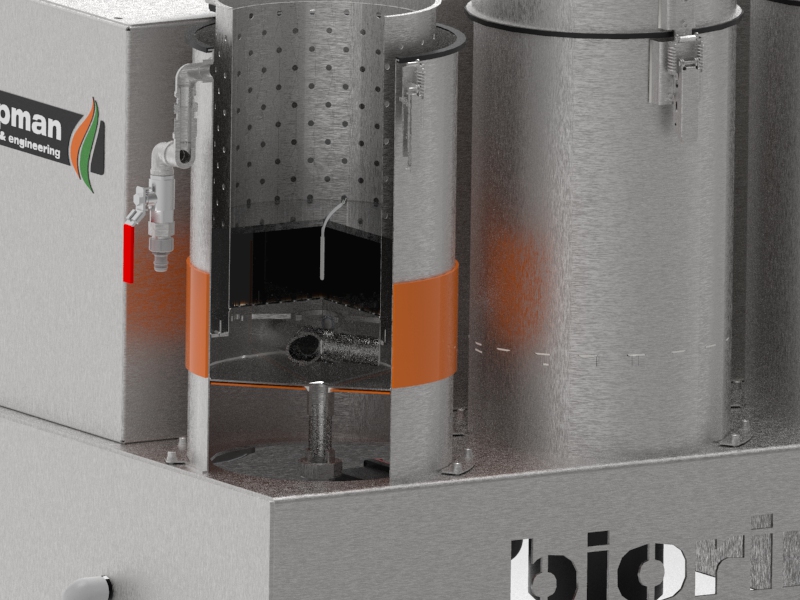

Because of the unique hot- or bleach- water- treatment, the pathogens in/on the seeds will be targeted while limiting any negative effects on the germination of the seeds. In this way, compared with the current (chemical) disinfection method, the hotwatertreatment brings a number of benefits. This includes quality gains, energy saving, less emission of harmfull substances, reduction of waste gases and a faster process.

Besides that, the possibly excess treated seed doesn’t need to be drained as chemical waste.The BioRinse method is especially focused on the efficient running of long known hot- or bleach water treatment. The implementation of the BioRinse-installation ensures that each seed undergoes an identical Heat/Rinsing/Drying protocol.

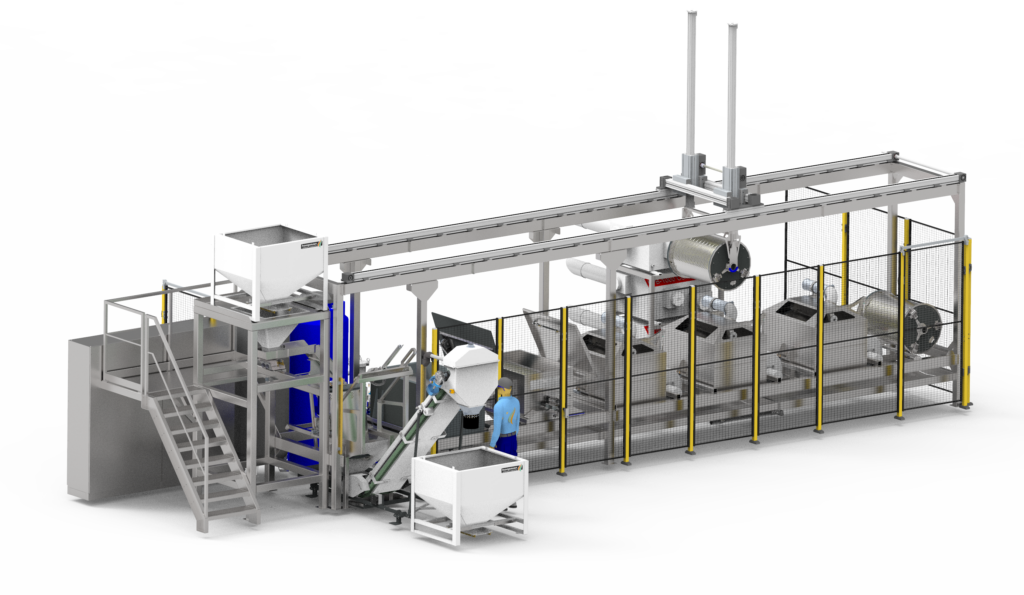

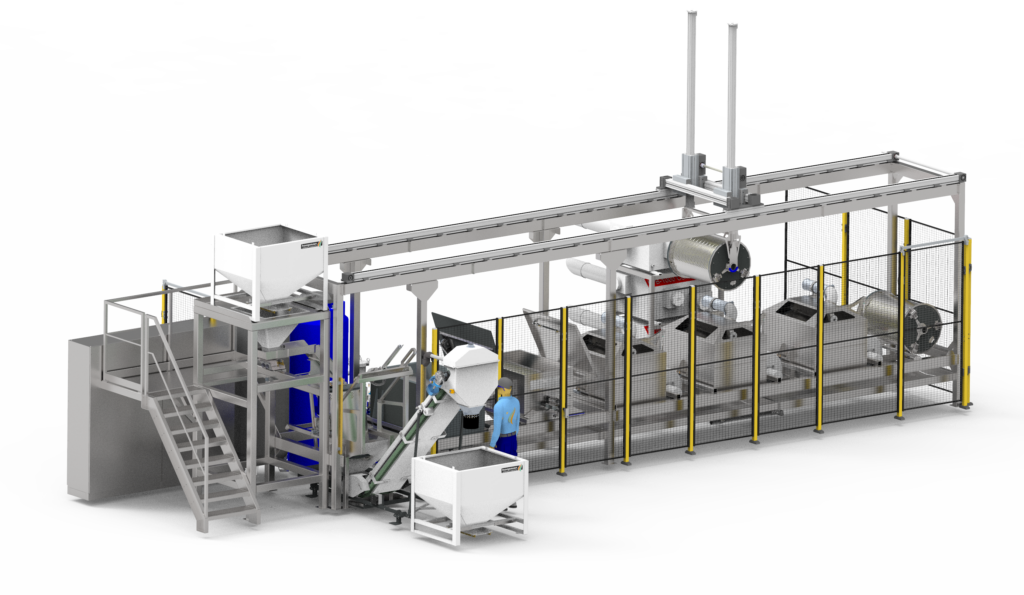

A steam based disinfection system was developed based on basic research done by TNO and further significally changed and refined during a regional government GoEfro r&d project, resulting in the current BioFlash line.

Both systems work of dry seed to dry seed; this also gives many logistic and quality benefits.

Priming effect: not only in BioRinse but also in the BioFlashprocess also germ-accelerating effects emerged. This makes sense because the superheated steam has a controllable abrasive effect on the seed skin; the dried back seed will faster absorb water at germination. Water-absorption is the principal start of germination.

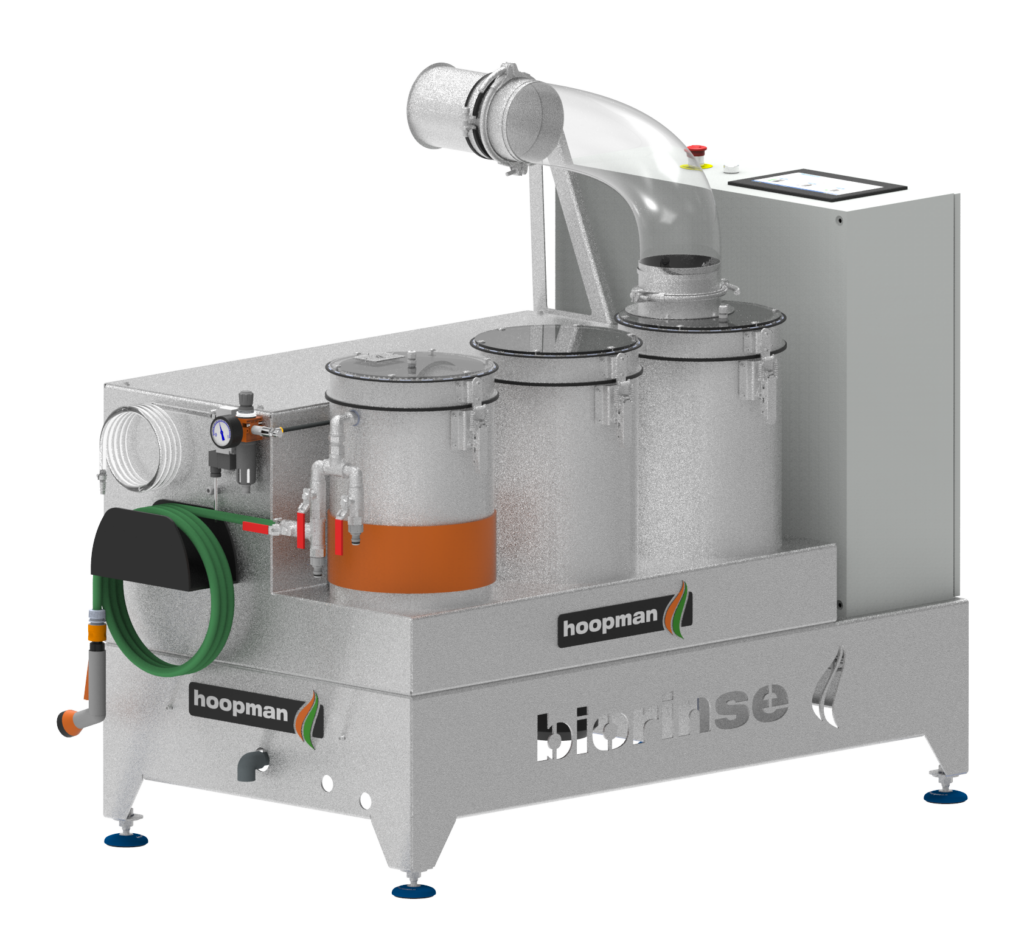

So for ‘physical’ disinfection, Hoopman has developed 2 new machines: the BioRinse and the BioFlash.

“Quick an Easy disinfection of seed lots”

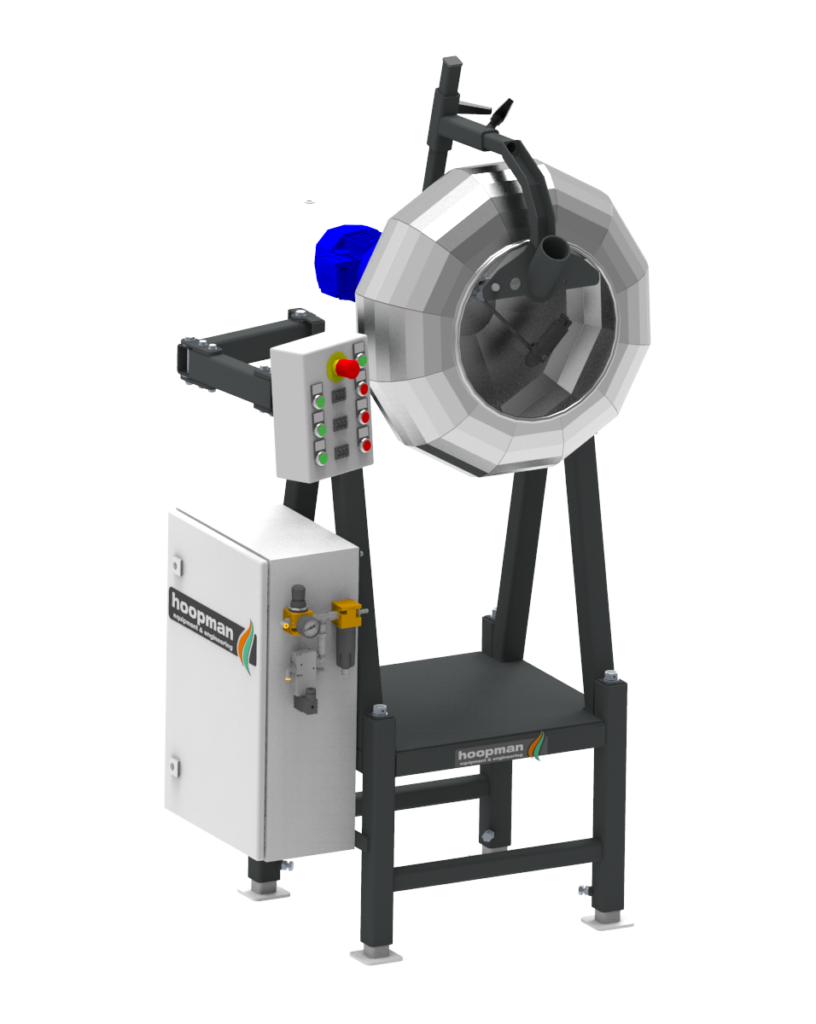

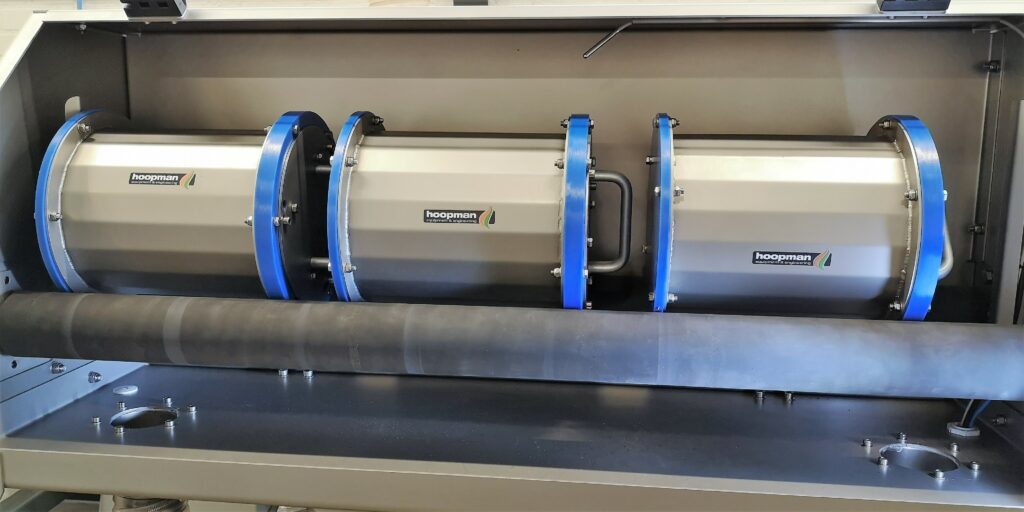

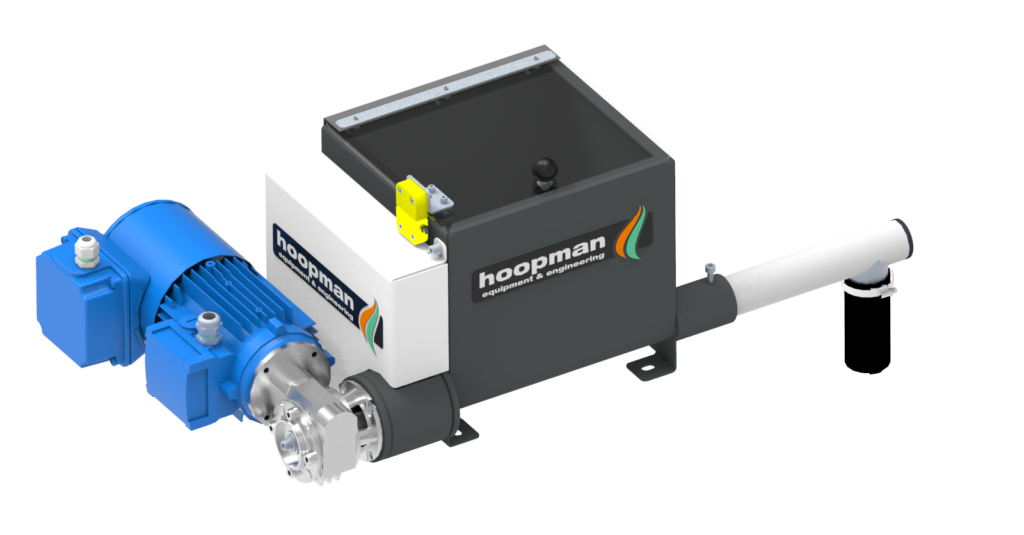

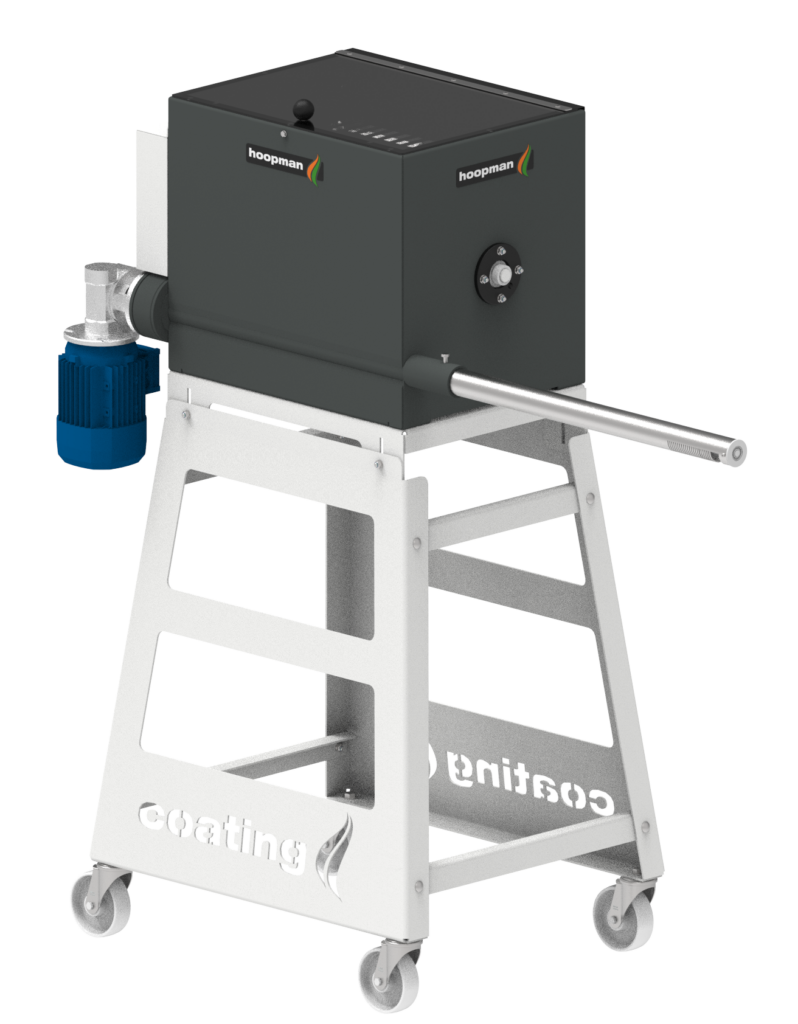

The BioFlash LAB is a brand new developed biologic disinfection system with already proven results on several seed species. The machine is developed together with several seed companies to prove the effect of the steam disinfection. The BioFlash Lab system gives you the opportunity to develop steam disinfection protocols and even do production of small seed lots. The machine is easy to use due to the intelligent software and protocol setup.

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

“The cornerstone of your future BIO Seed Treatment Technology!’

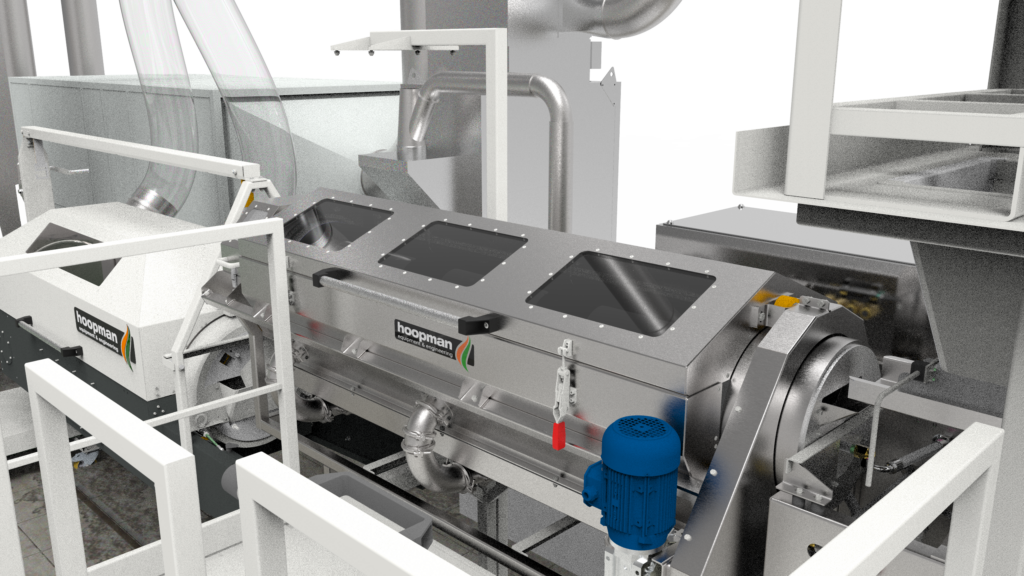

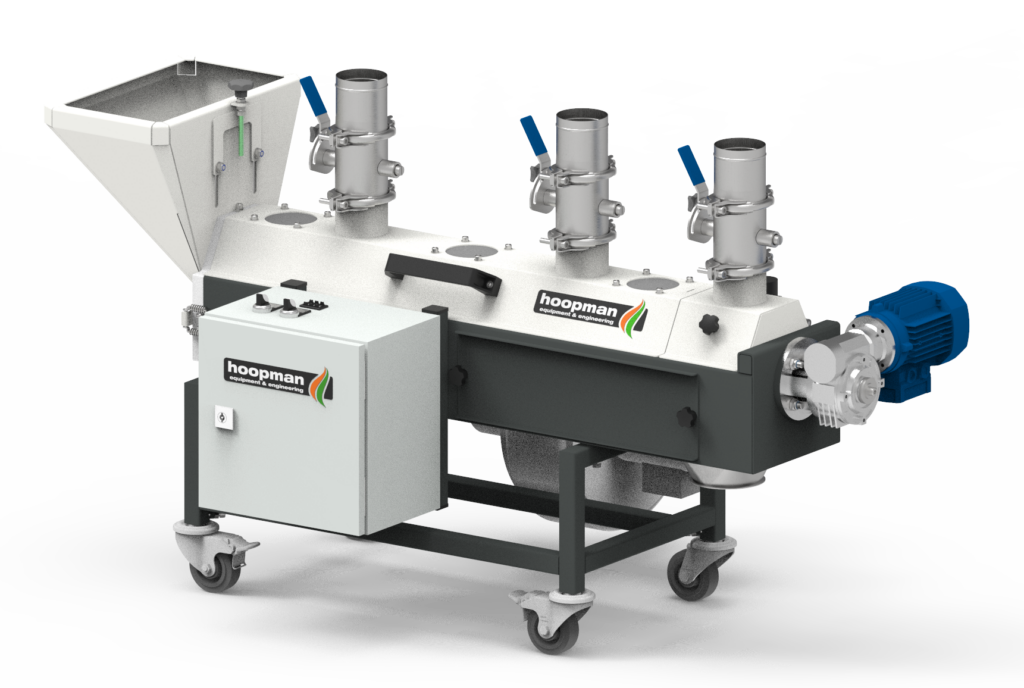

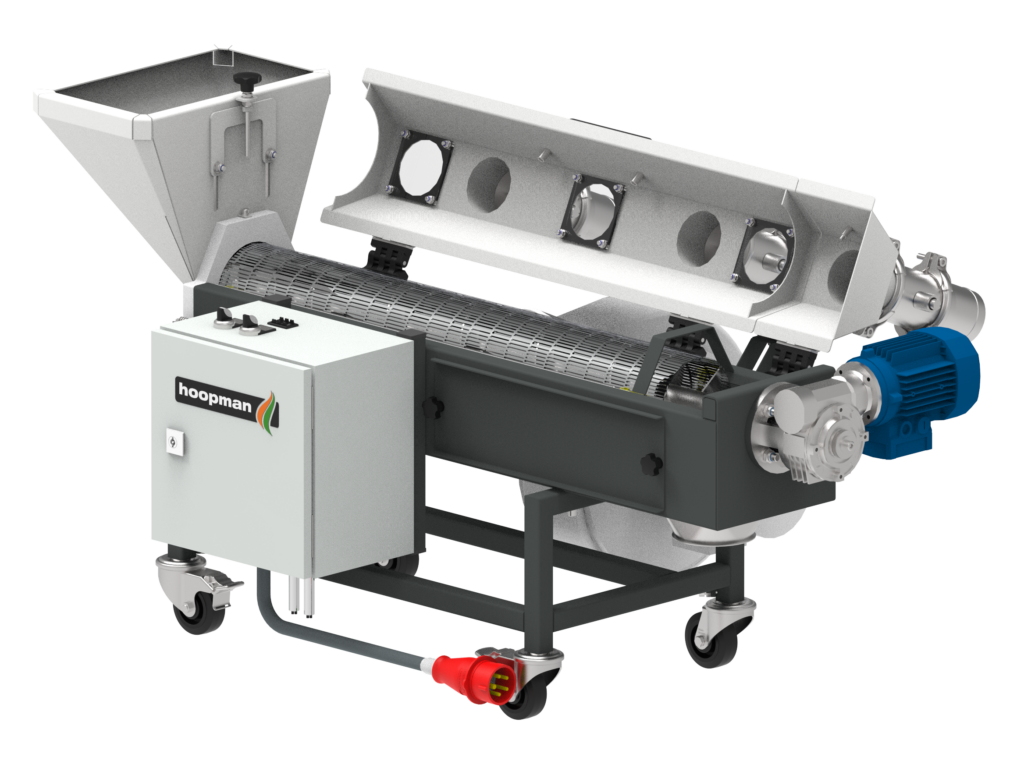

The new steam-based seed disinfection technology BioFlash® with continuous application, provides a broad cleaning of naked/treated seeds from most seed borne Fungi, Insects and Bacteria infections, without any loss of germination and seed vigour. Often germination and vigour of treated seeds increase and significant reduction in the development of various Fungi and Bacteria infections on leaves and ears have been discovered.

|

|

This simple to handle technology enables users a first step into development and optimization of their own seed disinfection technologies. Depending on the specific demands of seeds from different crops, further use of seeds and easier and efficient application of additional biological applications of beneficial fungi or bacteria such as Mycorrhiza ssp. , Pseudomonas ssp. or others.

Advantages BioFlash® Continuous disinfection system:

- Exact dosage of temperature, steam and time of treatment

- Modular use within existing seed treatment chains possible

- Medium space demand for hardware

- Open „software“ = know-how partnership with Hoopman is possible

- Low energy input and full traceability of applications

- Use for seeds both conventional and organic farming

Various seed treatment capacity installations are available/under development (Various BioFlash® units)

Want to know more? – Ask our sales team!

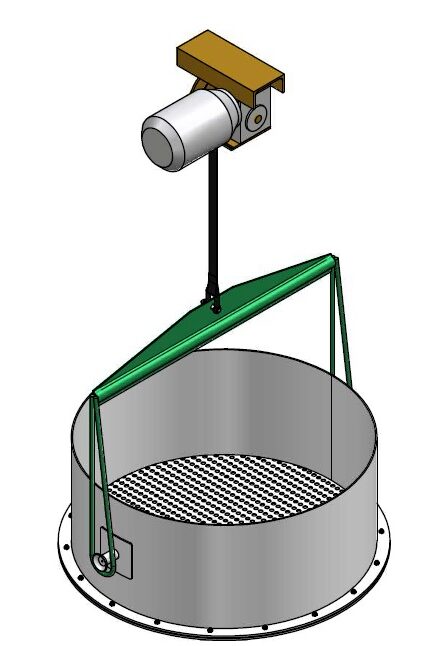

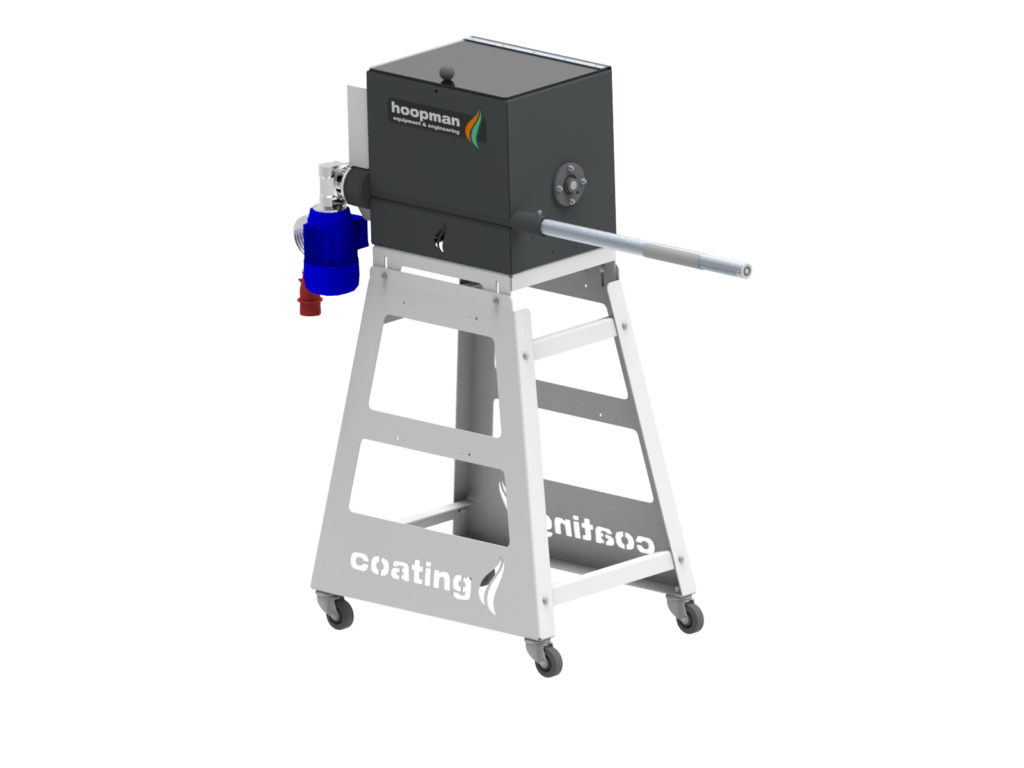

The BioRinse 5L system is designed for hot water treatment, rinsing and even priming.

The “base” of the system is a 16L drum, suitable to be used for up to 5L of seeds. The seeds will stay in this drum during the complete process, the drum can be placed from the rinsing station, into the centrifuge and then into the dryer. This means the seeds go in dry and at the end of the process the seeds are dry again.

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

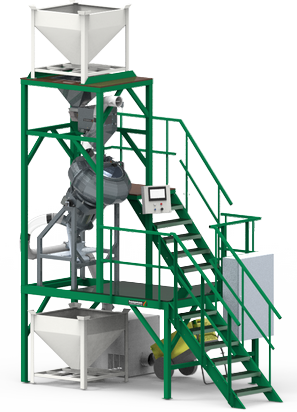

“Modular system, can be designed to meet your specs!”

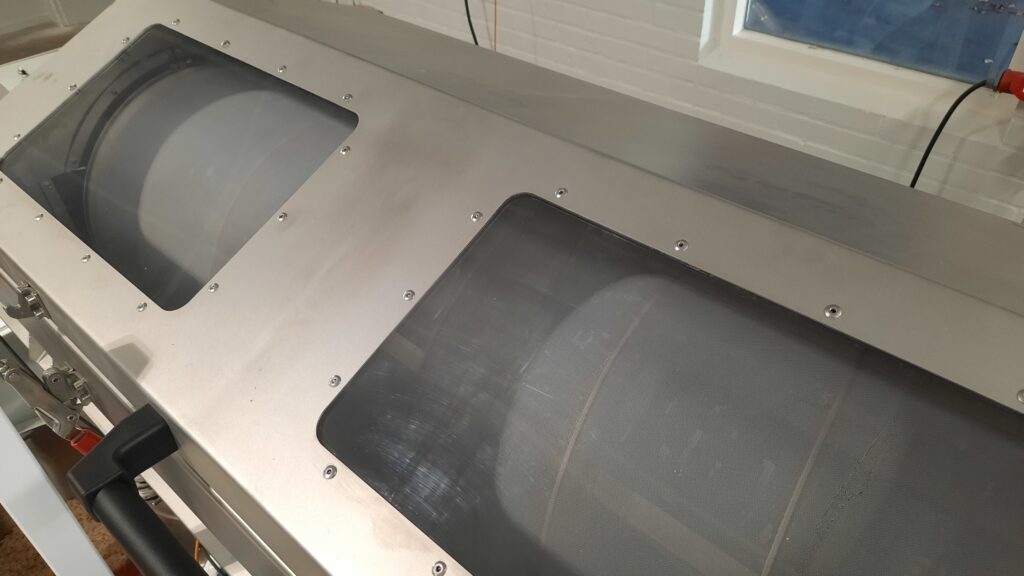

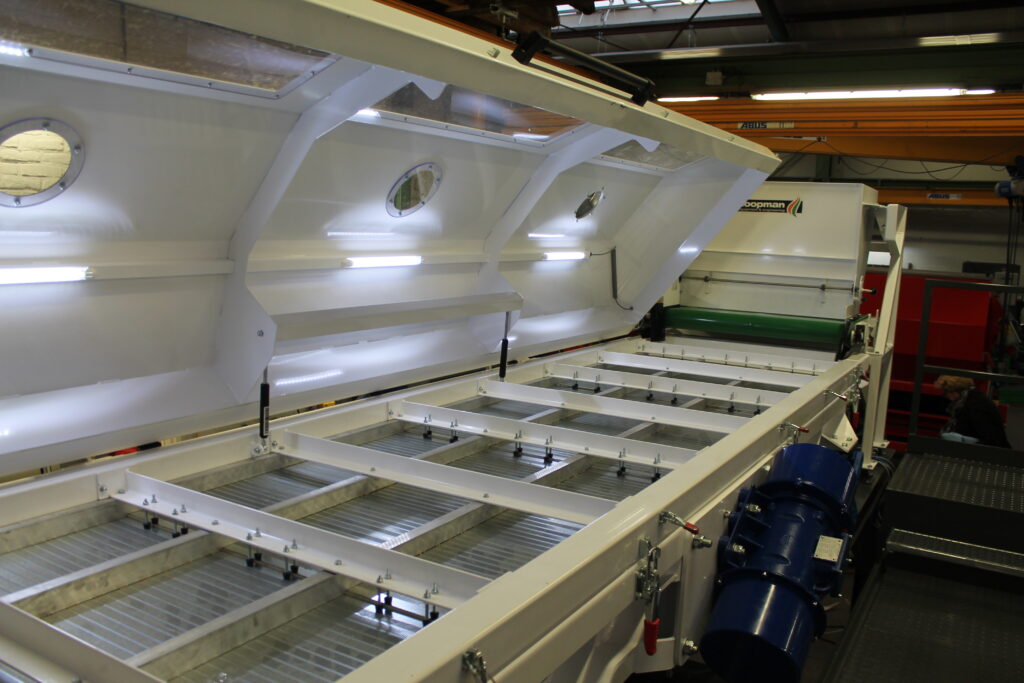

The BioRinse system is designed for liquid treatment protocols such as hot water treatment, rinsing protocols and even “drum priming” like protocols. The system can be configured from manual up to fully automatic with container-container setup.

The ‘base’ of this modular system is a 200L drum. The seeds will stay in this drum during the complete process.

The drum can be moved from the Rinsing module to an optional Centrifuge module. The Centrifuge module can also be included with an extra Rinse/Cool-Down option.

After the Rinsing/Centrifuge module(s) the drum can be moved to the Drying module.

The Drying module is put on weigh cells and therefore the seed can be dried to original seed weight according to whatever fast/slow protocol.

See therefore Priming – BioPrime 100L if you want to combine Rinsing protocols with Priming protocols.

Watch the video to see a demonstration of our latest version:

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

“Rinsing-treating station, easy & flexible rinsing of seeds”

The box of the BD-300 can also be used as rinsing box. We have designed a special rinsing station which is capable to rinse/treat seeds with liquid protocols such as “Hot water treatment”. We have several options available and can configure this system based on your specs.

The BD-300 box can be easily placed into the system with a forklift. After placing the box you can start a rinsing-treatment protocol with the PLC controlled system. You can pre-set up to 99 type of protocols, this gives you the opportunity to pre-set treatments.

The BD-300 box can be easily placed into the system with a forklift. After placing the box you can start a rinsing-treatment protocol with the PLC controlled system. You can pre-set up to 99 type of protocols, this gives you the opportunity to pre-set treatments.

The system can be configured with several water options, holding tanks, water heaters etc. Depending on your request. The most simple version is equipped with 1 holding container, a centrifugal pump for filling and/or continuous circulation of water. The water will be heated with an in-line heating system.

After you have finished the treatment, you can place the box in the dryer to dry back the seeds to the requested absolute moisture.

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

“Modular system, can be designed to meet your specs!”

The BioPrime 100L system is designed for liquid treatment protocols such as hot water-/bleach treatment, rinsing protocols and even “drum priming” like protocols. The system can be configured from manual up to fully automatic with container-container setup.

The ‘base’ of this system is, as with the BioRinse 100L modular system, a 200L drum.

Liquid Matrix Priming can be executed in the Rinsing (water-uptake) module and Drum Priming can be executed in the Drying/Drum-Priming module.

The Drying/Drum Priming module is put on weigh cells and therefore the moisture content of the dry seed can be increased as in a regular ‘Drum-Priming-Only’ set-up or (very slowly) dried back according a so called ‘Reverse-Drum-Priming’ protocol.

Movement of the Drum can be done manually but also fully automatically. Even including Drum Feeding/Unloading system i.e. container > container set-up.

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

“Multifuncional Priming cabinet for protocol development”

The Priming Cabinet is a multi-functional priming system which is perfect for developing liquid matrix priming protocols. Due to the design the cabinet is easy to use, each priming cylinder can be easily placed with quick connecting clams. With a heating element the individual temperature inside the priming cylinder is controlled, by adding compressed air to the process the seeds are homogenously mixed for the best priming results.

Each cylinder can run with its own day/night and temperature regime for testing several protocols at one run.

A “sophisticated” control system with logging to have more sight on the complete process is included.

We also deliver commercial sized priming systems on spec

Fill in the form below and a link to the PDF-file will be shown.

“Simple and straight forward design for Drumpriming”

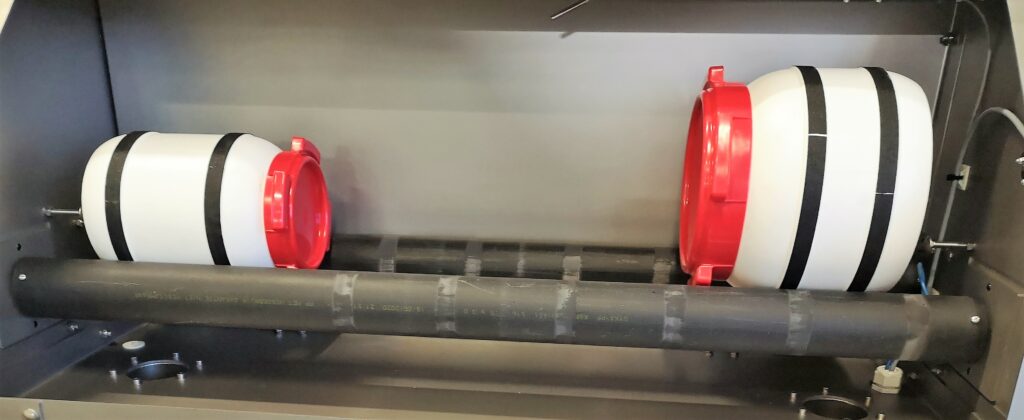

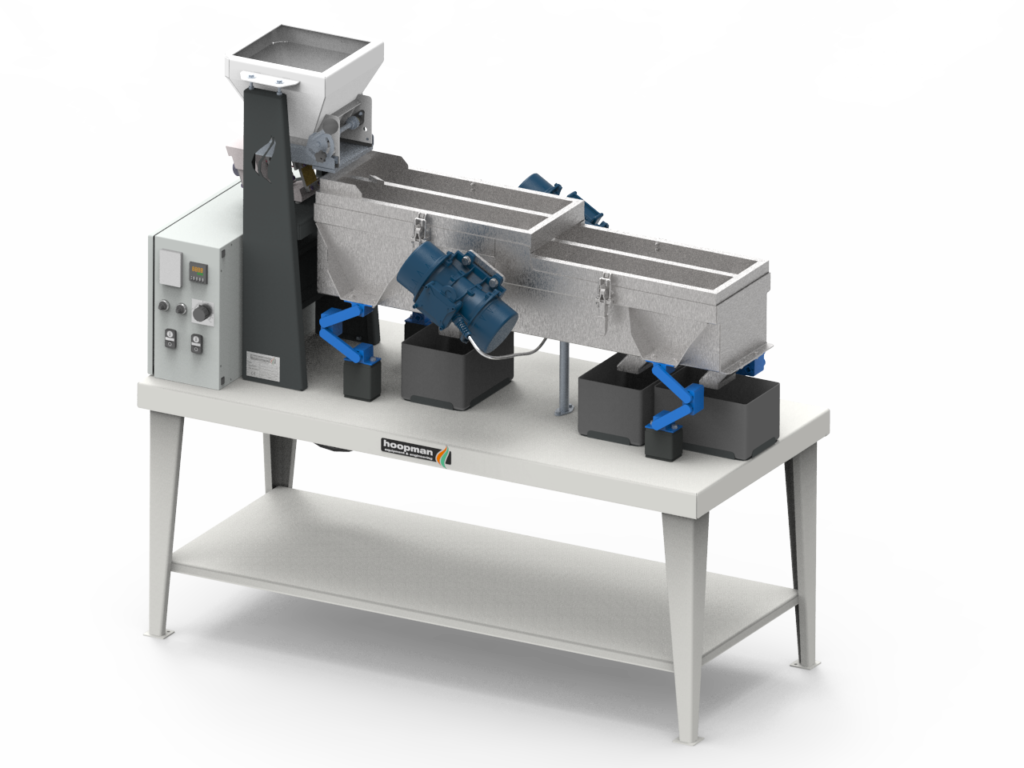

The Drumpriming Quattro System is a simple and straight forward designed drumpriming system for up to 6 cylinders of 6L gross volume. The top doors can be easily opened so that the drums can be put onto the rotating system. After closing the doors the rotation can be started.

Safety switch in the door system. As soon as the doors are opened, the rotation will stop automatically to protect the operator from rotating parts.

Standard delivered with 3x 6L and 3x 10L plastic drum (optional with stainless-steel drum with small mixers).

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

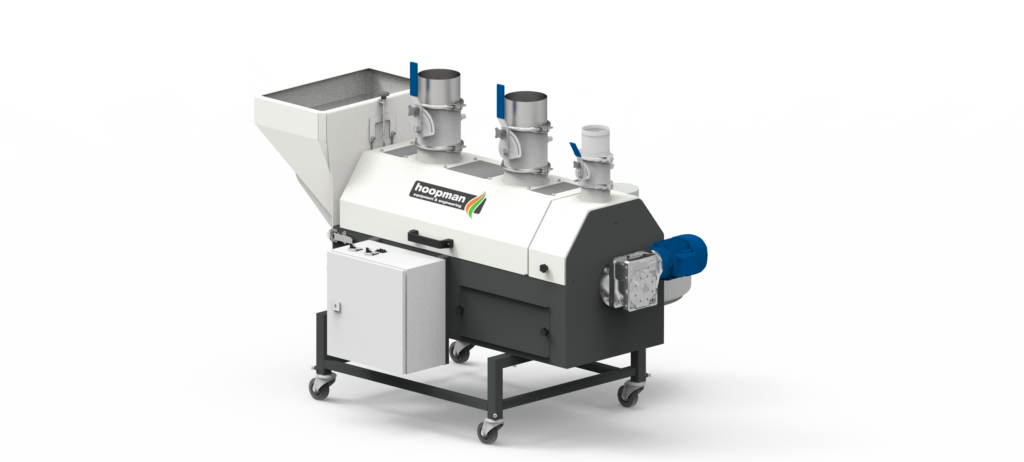

“Multipurpose Liquid Matrix Priming”

One unit, many possibilities. That’s the Multipurpose Primingunit.

Hoopman delivers several different priming units and has the possibility to make them meet your needs.

Available in a large variation of modules and sizes.

- All thinkable liquid matrix priming protocols possible

- All chemical and/or hot water treatment protocols possible

- 100% Batch Control

- 100% Batch Integrity

- 100% Hygienic

Also deliverable as Lab unit; see Lab Liquid Matrix

More information about our Multi Functional Matrix Seed Treatment System?

Please contact us: +31 (0)543 47 04 96 or fill in our contactform

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

Hoopman delivers many different dryers, for small quantities up to big fully automated dryers.

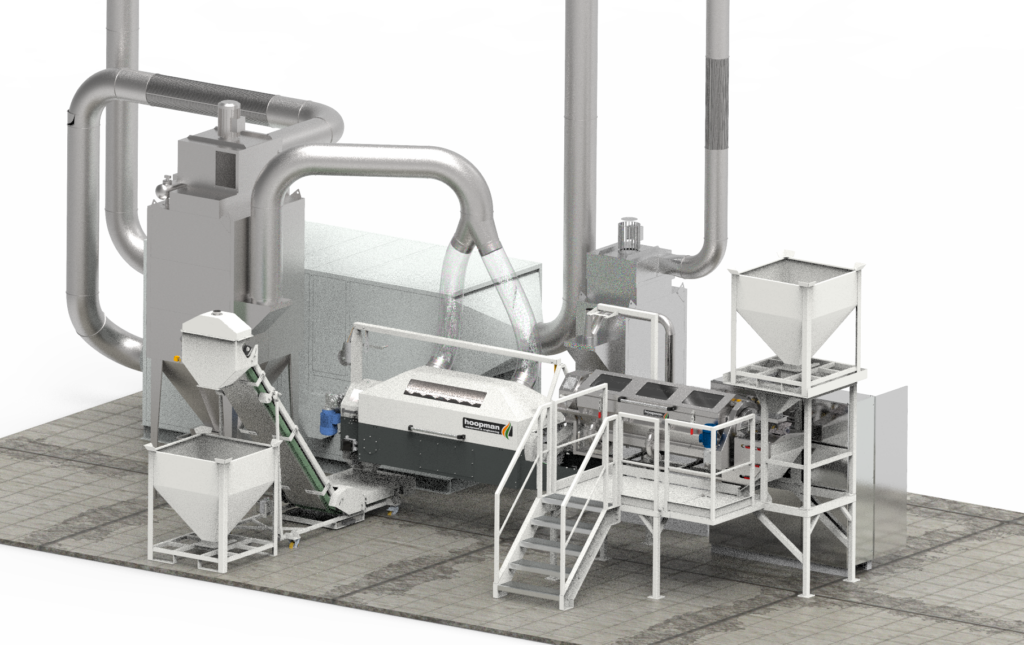

One of our new developments is the rotary fluid bed dryer. This dryer combines a high capacity with a compact design. The RFBD in combination with a rotary coater makes the perfect combination for a continuous automatic coating system.

“One Unit, many possibilities and made “On-Spec”

Hoopman, based on years of practical experience, has developed and sold various liquid matrix treatment systems.

They are now available in a large variation of modules and sizes and can handle simple standard or complex bespoke seed company protocols for:

-

Seed Priming

Liquid matrix priming is very common practice for many seed priming protocols, particularly for small to medium batch/lot sizes.

Seeds can be primed in water + additional components for osmotic potential control + dormancy breaking substances etc.

-

Seed Disinfection

Liquid matrix disinfection is also a very common practice and part of many seed disinfection protocols such as the (approx.) 45 minutes (approx.) 45 °C ISTA hot water treatment.

In our modular liquid matrix seed treatment unit(s) also seed disinfectants such as chlorine can be added. Also ‘Thiram steeping/soaking’ protocols can be performed consistently

-

Liquid Density Separation

During many of the above protocols separation of floating/sinking seed is relevant. Our systems can be supplied with decanting and/or draining systems to perform such separation exercises consistently and according to GLP standards also taking labour (safety) conditions in mind.

For more information on our Multi Functional Liquid Matrix Seed Treatment Systems fill in the form below and a link to the PDF-file will be shown.

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

Hoopman delivers many different dryers, for small quantities up to big fully automated dryers.

One of our new developments is the rotary fluid bed dryer. This dryer combines a high capacity with a compact design. The RFBD in combination with a rotary coater makes the perfect combination for a continuous automatic coating system.

“New design for a larger capacity and easy to handle”

The FBL is one of our smallest dryers, which should be in every seed coating/pelleting laboratory. It is specially made to dry small seed lots with the fluid bed principle. The new design makes the FBL capable to dry lots from 0.2 to 8 litres. (Depending on products used). Because of the temperature controlled integrated heating system the seed temperature is monitored during the drying process.

The FBL is one of our smallest dryers, which should be in every seed coating/pelleting laboratory. It is specially made to dry small seed lots with the fluid bed principle. The new design makes the FBL capable to dry lots from 0.2 to 8 litres. (Depending on products used). Because of the temperature controlled integrated heating system the seed temperature is monitored during the drying process.

The material cylinder is easy to change, just pull it out of the machine, empty it, and put in the next sample of seeds. Optionally a smaller cylinder can be delivered to dry lots from 200gr up to 2 liters.

Because of its technical design the noise of the dryer is very low. The frequency controlled fan in combination with the isolated air outlet makes it a very userfriendly machine. This is very important for most of the laboratory equipment.

Standard equipped with

- Standard plug and dry version

- Integrated electrical heating system

- Material cylinder for up to 6-8 litres of seed

- 400V standard connection

- Standard mounted on 4 swivel wheels, dry wherever you want

- Low noise, because of the technical design

- All advantages of a low-budget fluid bed system

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

“Simple and easy drying of small seed lots”

The Fluid Bed Mobile Dryer is one of our most flexible dryers available, it can dry almost everywhere in your company. It just needs a power connection and it is ready to dry. With the internal heating system combined with a PI controlled thermostat the temperature of the seeds never get to high.

The Fluid Bed Mobile Dryer is one of our most flexible dryers available, it can dry almost everywhere in your company. It just needs a power connection and it is ready to dry. With the internal heating system combined with a PI controlled thermostat the temperature of the seeds never get to high.

The simple operating panel is very easy to use, just set the right amount of drying time or dry constantly. A valve on the air fan makes the airflow adjustable so you can set it to an optimal fluidized bed. After the drying process you release the drying container and empty it into your next process step.

For the emptying out of the aluminum material hoppers we have a special lifting device available, see the MCED in this catalog.

Standard equipped with:

- Most efficient fluid bed system available in the industry

- Standard ‘plug and dry’ version

- Electrical PI controlled heating system

- High flexibility, mounted on 4 swivel wheels, dry where you want

- Standard with 110 liter (gross) aluminium bucket and can dry 40-60L of seeds (depending on the process and species)

- Drying on time or continuously

| Option: RH upgrade with PLC control and logging |

Option: 3-Box adapter |

|

|

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

“Vibrating sieve with an innovative sieve changing system”

The NEW state of the art VCS600 sieving system makes accurate calibrating and sieving of your seeds much easier. Due to our special designed sieve clamping system, you can now easily exchange your sieves.

The sieve system is standard equipped with an inlet system, dust/noise hood and control box to make it plug & play. You can place 3 sieves of 600x800mm inside the frame to sort your product into 4 fractions.

Key features:

- Easy to open for inspection, no loose parts

- No-tool sieve changing system

- No sieve plate frames prevents expensive sieves

- Scalable system for lab scale up to high volume sieving

- Add extra sieve boats in order to do 7 or 10 fractions in one run

Watch the video to see a demonstration of our latest version:

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

“Easy batch drying system for averege lots of primed and/or pelleted seed”

The FB Cabinet Dryer is one of our cabinet dryers especially made for customers who wants to dry pellets or naked seeds in a simple-straight forward Fluid Bed Drying principle. We make this system modular, which means that it can be upgraded to a fully conditioned and weather-independant system.

|

|

| FB Cabinet | FB Cabinet conditioned |

The FB Cabinet Dryer uses the same material container as the FB Mini Dryer, but the FB cabinet has an advantage that it can be coupled to a dust-extractionsystem and being equipped with a conditioning system.

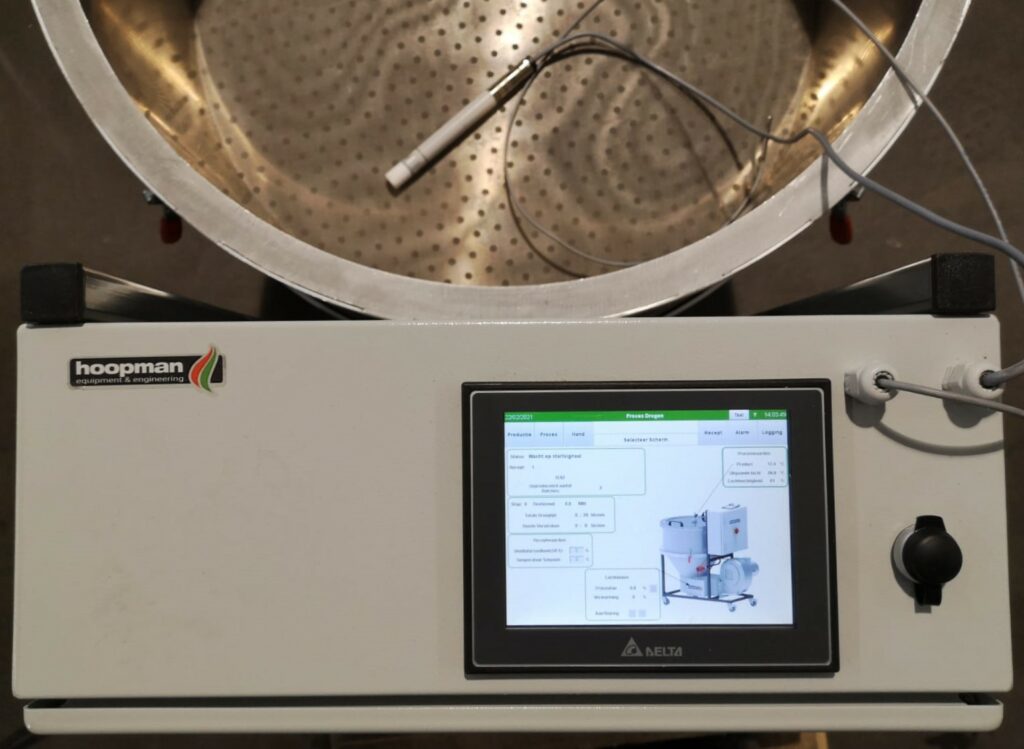

Each FB Cabinet system is standard equipped with a PLC and 10″HMI control system. This system gives you the opportunity to log drying details and store and repeat drying protocols.

To ease the emptying of the material containers, we deliver a special system. For more information about this system see our MCED.

Standard features:

- Fluidization through negative pressure

- Aluminium holding bucket (100ltr)/mild steel cart holding approx. 1.000.000 wet pellets or approx. 100 liter seed

- Control Box equipped with:

- PLC controlled system

- Frequency controlled main fan (4kw)

- 10″Vipa TFT screen

- Local logging of temperatures / process with USB export function (CSV)

- Standard plug and play version

- Air inlet directly through heat exchanger 1000x400mm (20kW)

- External hot water circuit to be connected

- Standard with 5P 16 round EU connector

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

“Fluid-Bed drying with high capacities and easy to use drying box”

The BD-300 is designed for drying bigger lots of coated, pelleted or treated seeds. The technical design is basically our BDS drying system but with all advantages of a removable drying box. This gives you the opportunity to load one box while the other box is being dried. The boxes are designed to fit in already existing hot-water treatment plants for wooden boxes. The drying box will be placed into the machine and is held in place by specially designed clamps. At the beginning of the process the dust extraction hood closes so that all seals are compressed and no air is lost during the drying process. Because the complete frame is placed on load-cells you can monitor the moisture decrease during the complete drying process. Another advantage of this system is that in the beginning of the process the complete box tilts backwards/forwards to have a homogenous fluidisation as soon as possible.

The drying box will be placed into the machine and is held in place by specially designed clamps. At the beginning of the process the dust extraction hood closes so that all seals are compressed and no air is lost during the drying process. Because the complete frame is placed on load-cells you can monitor the moisture decrease during the complete drying process. Another advantage of this system is that in the beginning of the process the complete box tilts backwards/forwards to have a homogenous fluidisation as soon as possible.

All these features where already tested and designed in our BDS systems. But the biggest advantage of this BD system is the possibility to remove the box from the dryer and use it for transport/rinsing /treatment. The box is built of stainless steel and has special corners to be sure that the complete box is in fluid-bed while drying. The box can also be emptied with standard in use box tippers.

The system is controlled with a PLC and HMI which gives you the opportunity to set drying protocols with several steps (to slow down the fan when seeds get dryer), dry to pre-set weights and even a logging of all data is included.

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

“Flexible and easy drying of different products!”

This flexible and easy to use drying system is specially made for drying of non-threshed corn earns or other non threshed seed. However it can also be used to static drying of a multitude of different, smaller seed lot. You simply connect a moveable stack of containers onto the machine and start the drying process. The CDS system has 10 connections for 10 individual carts, with an automatic closing valve. When you disconnect a cart by pulling it out of the machine, the connection will automatically be closed.

The fan speed is regulated with a frequency controller so you can set the amount of airflow trough the seeds. A thyristor regulated heating system regulates the temperature of the airflow.

Product Charasteristics

- Integrated heating system (6 kW)

- Integrated process fan (2.2 HP)

- Fan + plenum is mounted on 4 swivel wheels, to make it highly flexible

- Automatic connection closing system

- PI electronic thermostat for highly accurate temperature setting and control

- Frequency controlled fan

- Very low noise though optional air-inlet noise reducer

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

“Automatic hand sieve for our standard wooden framed 480mm x 480mm sieves”

The new design of the RS480 reduced the noise, makes the placing of the bins more easy and is better according to safety.

This sieve is to quickly separate doubles/blinds from good pellets during start and finish of the pelleting process (in order to be able to come close to 100% recovery i.e. 1.000.000 seeds will give 1.000.000 pellets).

Every now and then the operator will have a small portion of pellets that need to be ‘cleaned’ from dust/seed/doubles/blinds. Typically about 2-4 times, some 100 – 1500 gr. of pellets/seed/dust/doubles/blinds will have to be quickly sieved.

Optionally we have a sieve storage cart system available to store all your sieves in an easy way. This cart is standard mounted on 4 swivel wheels which makes it flexible and easy to use.

Standard equipped with:

Easy ‘no bolt – no tool’ sieve exchange

- Minimal moving parts

- Simple design

- Easy and quick sieve cleaning guaranties seed lot integrity

- Low noise due to our new technical design

- Easy bin placing and removing

- Moveable with a pallet car

- 2 plastic buckets included

- Standard 480mm x 480mm sieves can be inserted to the machine

Infosheet – PDF

PDF Fill in the form below and a link to the PDF-file will be shown.

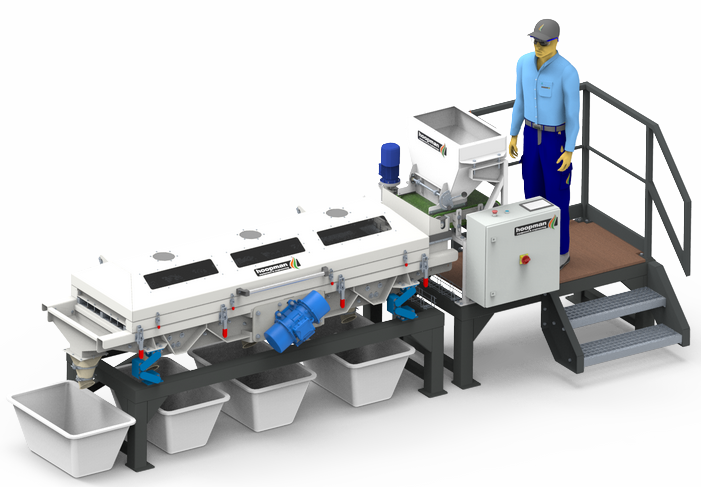

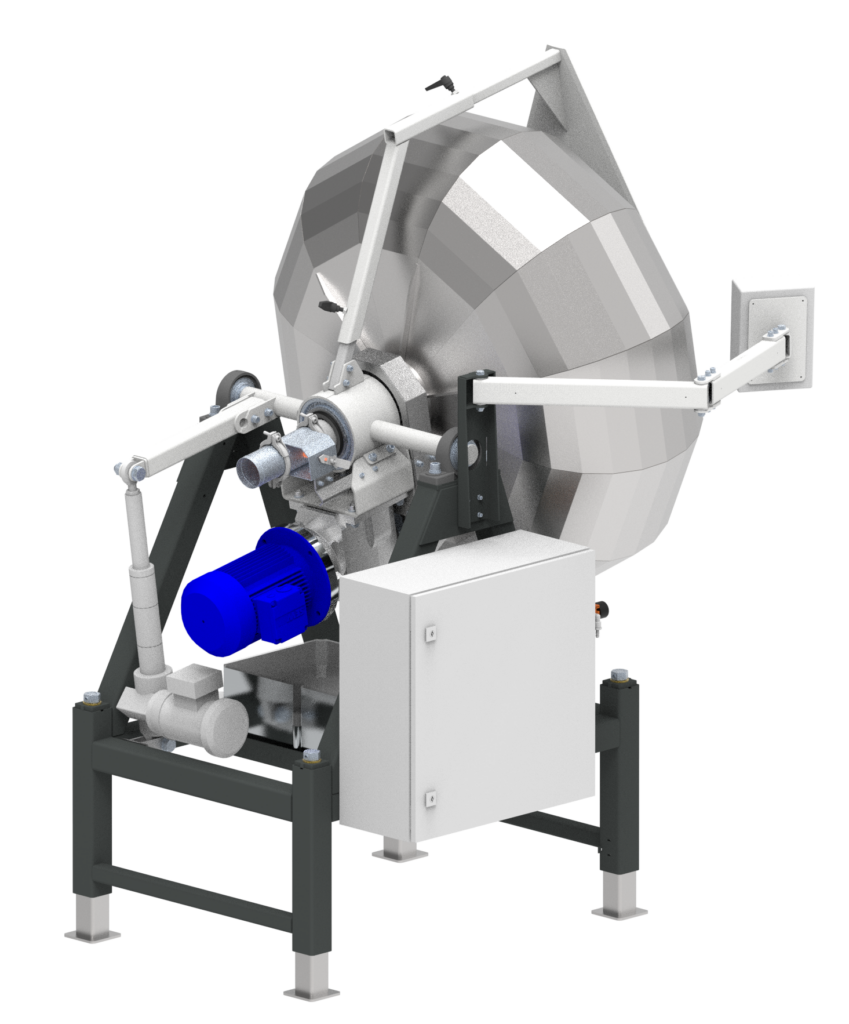

“Continuous drying with a batch system!”

The Automated Batch Drying System combines highly efficient fluidised bed drying with ‘single batch containment’ advantages. This system is especially used for combined coating/drying of pelleted product. If pelleting time for example is 15-20 minutes, an accumulated 4 batches can be dried in about 60-80 minutes. Systems of 60–600 ltr. per batch are available. This results in fully automated coating/drying systems with a capacity of 120–1800 ltr per hour coating/drying capacity.

Another huge advantage of the design is that real-time weighing can take place during the drying in order to have absolute and continuous moisture control independent of often inaccurate in line/real time humidity control.

The dryer empties out 100% because it rotates 180 degrees so there is no cross contamination between batches!

Normally vibrating fluidised bed systems are, when compact, extremely costly or when simply built (reciprocating drive) extremely long. The Hoopman Automated Batch Drying System is extremely compact, efficient and moderate in cost.

If you want to know more about our automated batch dryer, please contact us.

Product Charasteristics

- Specially for encrusted and pelleted seed

- Rapid drying because of the fluidised bed principle

- Automated discontinuous system, traceability / containment guaranteed

- Real time humidity control

- Compact design

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

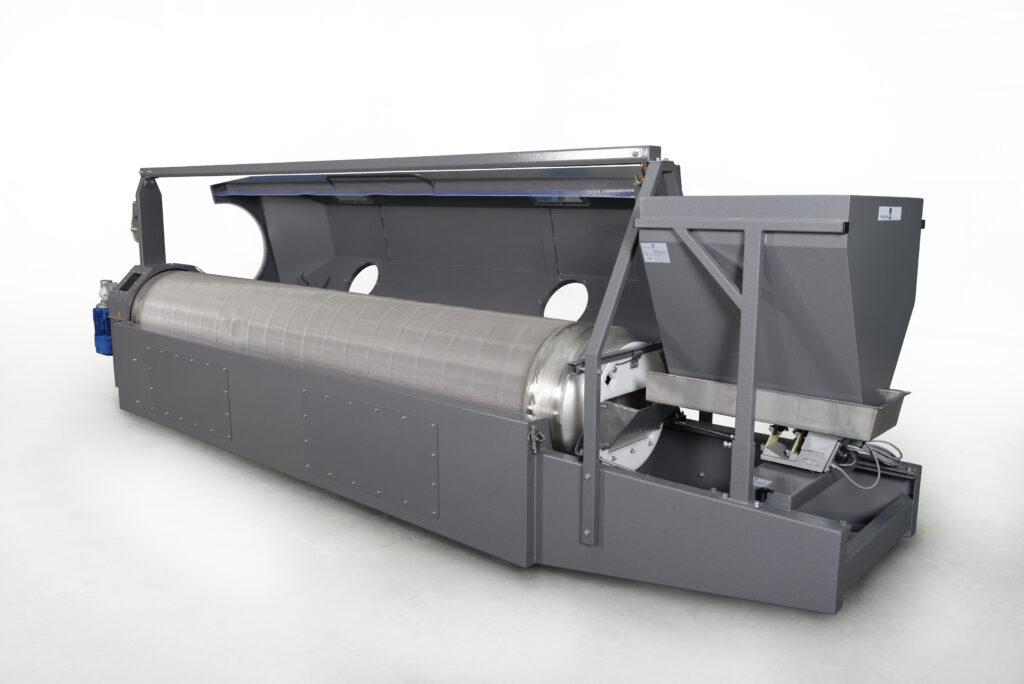

“Continuous fluidbed drying without a vibration system”

Filmcoating has basically taken over all conventional powder or slurry based seed dressing. The challenge of today are to maintain advantages of the high output of the rotary coating systems with an efficient continuous drying system.

In stead of using large static dryers or high cost vibratory dryers, the e&e Continuous Rotary Fluid-bed drying system combines the speed and efficiency of a fluidised bed system with the simplicity of a continuous rotary drum dryer.

This brand new and unique system is now available for testing in our facilities in Holland.

– RFBD600-19, Designed to keep up with a HR800 coating capacity

– Several other types available for short conditioning and high capacities

If you want to recieve more information, please contact us

Product Characsteristics

- Non-vibrating system

- Selfcleaning system

- Simple straight forward design

- Continuous fluid-bed system for optimal drying

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

“Simple and accurate sieving of your seed”

The CSS400 is a sieving system which calibrates with a rotating cylinder. This machine is often used in pelleting processes to calibrate the pellets on its shape. The power of the machine is the simple design, and the ‘no-tool’ sieve changing. This highly flexible and simply design makes this machine perfect for your pelleting process.

Product characteristics

- Excellent, consistent and electronically variable product dosing on cylinder

- Easy ‘no bolt – no tool’ cylinder exchange

- Minimal moving parts

- Simple design

- Easy control panel for dosing speed and rotating speed (With the CSS-400 –I)

- All machines have a frequency controlled dosing system

Watch the video to see a demonstration of our latest version:

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

Infosheet CSS400

To make the emptying of the material containers more easy, we have developed an adaptable Material Container Emptying Device.

We have several standard mounting options available, for example one you simply mount on a wall or one that can be mounted on the building ribs.

Advantages

- Simple unloading system for the material container of the FBM, FBOA, FBCRA

- Several standard mounting options available

- Adapters for your seed bins available

- Electrical lifting device

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

With Drying Beads® you can dry directly whitout using a conventional drying system. The Drying Beads® can be directly put into your seed package.

When the Drying Beads® are full of water you can easily regenerate them by putting it into an oven. This product is especially usefull at locations where you do not have a conventional dryer available.

Click here for a video of the Drying Beads

For more information see the attached PDF or contact us.

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

“Lab conditioner to de-dust and cure film-coated seeds”

Dust and chemical application on seed is an extremely sensitive issue in Europe and is also considered as a challenge in other parts of the world.

Crop protection products registrations have been temporarily put on hold (with huge financial implications) due to the two major pesticide bee related incidents that have occurred within the last 10 years. This is the reason that Hoopman did rebuild their rotary fluid bed system to make “low cost” conditioning/de-dusting possible!

By adding a Hoopman conditioner to your already in place treatment system you can easily de-dust and cure your treated seeds.

“The pelletingpan for all your flower seeds and/or little charges of 5-250 gr/batch”

The PC-S has been developed specifically for the pelleting of flower seeds and vegetable seeds small parties (20-250 g per batch). This makes the machine ideal for small batches of pelleting for example, in a laboratory environment.

With our segmented panmanual mixing is no more necessary, because of the corners the seed mixes by itself. The combination of the standard delivered liquid syringe with optional fluid pump ensures that there is a homogeneous beam on the seed. Along with the PF-35 powder dosing device, which is a very homogeneous powder output has what looks like a powder curtain, you have the best machine for your conventional pelletingproces.

By the design of the front plate with suction you have optimal access to the pelletingproces. The lighting and the flexible head machine will make sure you get to follow the process and affect.

The machine can be equipped with various standard operating possibilities. A “basic” on/off model to an extensive panel where you will find all the functions at your fingertips.

Features:

Features:

• Unique segmented drum for optimal material mixing and movement

• Optional ‘all-in-one’ simple operation for the pump, dosing device and the rotation speed

• 100% access to the process

• Pan height and angle are adjustable

simple design

• Plug and play standard version

• Various pan sizes possible

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

Hoopman offers various systems for calibrating and sizing.

For sizing of pelleted seeds, we can offer you the CSS400 drum grader which is easy to operate: sieve change without any tool. If you want to size/calibrate seeds with the highest level of accuracy, then our VCS600, a vibrating callibrating system, would be a good choice.

PC-L

The pancoater is still one of the preferred and most widely used machines for conventional pelleting. A key advantage of our pan coater is the special segmented pan. This creates an optimal mixing/movement of the seed, even directly after starting. Mixing by hand by the operator is no longer needed.

With our segmented pan there is no manual mixing more necessary because of the angles, the seed/coating materials mixes by itself. The combination of the standard delivered automated spray-gun with optional fluid pump ensures that there is a homogeneous spray on the seed. The optional PFR60 powder feeder, which has a very homogeneous powder output, that even looks like a ‘powder curtain’. With this package you have the best system for your conventional pan pelleting process.

Yet another great advantage of our pan coater is the dust extraction through the center/back of the pan. This brings the user/operator not in contact with the dusty process. This means also that there is a better access through the front. Together with the standard included halogen lamp this secures an optimal operator view of the process.

The default control box is equipped with a start/stop and speed setting for the pan, liquid-pump/spraygun and powderfeeder. On request, we can also deliver an electric pan angle adjustment.

Features

Unique segmented drum for optimal material mixing and movement

- ‘All-in-one`simple operation for the pump, dosing device and the rotation speed

- Dust-Extraction through the back, 100% access to the process through the front side

- Pan height and angle are adjustable

- Simple design

- Plug and play standard version

Infosheet – PDF

Please fill in the form below to show the link to PDF

“Manual coating with optimal material movement”

The pan coater is one of the most used machinery for manual pelleting. The big novelty of the pan coater is a special segmented pan for an optimal material mixing process without extra manual/hand work.

|

|

With our segmented pan there is no need of mixing by hand because of the edges the seed mixes itself. In combination with our standard delivered liquid spraying nozzle and optional pump a homogeneous liquid spraying is realized. Adding a PFR-60 powder feeder, which gives a very homogeneous powder output, like a powder curtain, you have the best machine for your manual pelleting process.

An other big advantage of the pan coater is the dust extraction at the back. This means that the operator is not in contact with the dust coming of the process. But before it reaches the operator it is exhausted at the back of the pan. This means a better view on the process and less dust into the room.

Every pan coater is delivered with a halogen light which gives an optimal view during the pelleting process.

With the standard control box you can start/stop and change the speed of the pan, the liquid pump and the optional connectable powder feeder. On request it is possible to supply an electrical angle changing system for the pan.

Product characteristics

- Unique segmented drum for optimal material movement / mixing

- ‘All-in-one’ simple control panel for pump, powder feeder and pan speed

- Dust extraction from the back, 100% acces to the process from the front

- Pan height and angle are changeable

- Simple straight forward design

- Plug and play standard version

Standard available pans for PC-XL

| PD940-430 | PD940-570 | PD1200 |

| 1 million pills | 1.5 million pills | 2.2-3 million pills |

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

“Laboratory sample cleaning / calibrating machine”

The VCS280 is used to clean/calibrate small seed lots, for example sample cleaning. Because of the very accurate sieving principle the calibrating is very accurate and reproducible. Due to the technical design, the machine is easy to clean and vibration of the table is held at the minimum. The vibrating will be absorbed by the flexible supports and prevents the machine from “walking away”.

Standard equipped with:

- Easy clean out fast sieve unloading system

- Adjustment of vibrating force (only necessary at extreme variations of product properties)

- Frequency controlled and settable vibration motors

- Standard mounted on table

- Standard delivered with 3 collecting bins

- Standard with 2 sieves, which means 3 fractions

- Easy settable angle of vibration motors

- Vibrator feeder seed inlet

Time between fast and normal vibration can be set to increase the self-cleaning process

Watch the video to see a demonstration of our latest version:

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

Infosheet VCS280

“The smalles powderfeeder from the series,

excellent for use in combination with HR350 / PC-S“

The PF35 is the smallest feeder from the standard series. This dosing device has a capacity of approx. 0.1-1 l/min which is perfectly in line with the necessary capacities for a typical HR350 or PC-S process.

All PF machines are equipped with a mixing arm for prevention of separation and bridging. This ensures that the different components cannot DE-mix during the pelleting and/or coatings process. For complete automatic systems there are loss in weight and/or pre-weigh systems available.

Features:

◦ Supplied with a plug for connection to a pancoater/rotary coater, so no external power supply necessary

◦ No bridging or segregation of the product

◦ Constant powder dosing for a good and consistent build-up and calibration

◦ Empties almost completely, and is therfore easy to clean

◦ Standard mounted on 4 swivel wheels for optimum mobility and flexible access to coating device.

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

“Vibrating sieve with an innovative sieve changing system”

The NEW state of the art VCS1000 sieving system makes calibrating and sieving of your seeds much more easier. Due to our special designed sieve clamping system you can now easily exchange your sieves without having parts lying around everywhere.

The sieve system is standard equipped with an inlet system, dust hood and control box to make it plug & play. On the display you can set the speed of the vibration, the inlet system and also control the high-speed / low speed switching for accurate and auto cleaning of the sieves. Depending on the system you can hold 3 or 4 sieves of 1000x1000mm in the sieve boat to sort your product into 4/5 fractions. By combining several sieve boats you can even go up to 6/8 or more sieves in one run.

Because there is a ball-frame with balls underneath the sieve frame, it will clean itself during the sieving process. By frequently vibrating at a higher speed, blockage of the sieve slots will be prevented.

Because there is a ball-frame with balls underneath the sieve frame, it will clean itself during the sieving process. By frequently vibrating at a higher speed, blockage of the sieve slots will be prevented.

NEW DESIGN, less noise, easy to change sieve system and dust extraction

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

In this section you find more information about our coating machinery. If you want to coat small amount of seed and do it manually you should look at our Pan Coaters. If you want to coat bigger amounts of seed, or even thinking about automatic coating you should look at our rotary coating equipment.

Because of the increasing amount of liquids on the seeds they need to be dried after the coating process. Hoopman equipment & engineering b.v. has a range of dryers which you can find in our drying equipment part of this site

“Coating with high capacity and speed”

New technical design, long-life/wear resistant and better interchangeability at service!

In recent decades, the rotary coating developed and has become a standard for efficiently and accurately coating. The principle of a rotary coater is based on a mixer, but without paddles or other moving parts that could damage the seed.

Why a coater of Hoopman equipment & engineering?

Hoopman equipment & engineering b.v. has more than 35 years of experience in the coating of seeds and making machines for coating of seeds. This makes the details of the machines based on years of user experience.

“The most commonly used powderfeeder from our range,

specially designed for pilleerproces in a HR600 / PC-L“

The PF38 is one of the most widely used powderfeeders from our series. This doseur has a capacity of approx. 0.1-2.6 l/min which is great in keeping with the necessary capacities for a typical HR600 or PC-L process. In addition, this to provide different default doseur transmissions whereby the proceeds can be perfectly adjusted to your specific process.

All PF dosators are equipped with a mixing arm for prevention of separation this ensures that the different components cannot UN-mix during the pelleting and/or coatings process. For complete automatic systems there are loss in weight and/or pre-weigh systems available.

Features

◦ Supplied with a plug for connection to a pancoater/rotary coater, so no external power supply necessary

◦ No bridges or separation of the product

◦ Constant powder dosage for a good and consistent calibration

◦ Empties almost completely, and is easy to clean

◦ Standard mounted on 4 castors for optimum mobility

Standard available capacities:

| PF38-S | PF38-M | PF38-F | |

| 0.1-0.6 l/min | 0.1-0.9 l/min | 0.2-2.6 l/min | |

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

“Medium-format coater for 800-1200 l/hr productions,

from manual to fully automated”

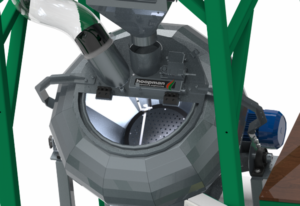

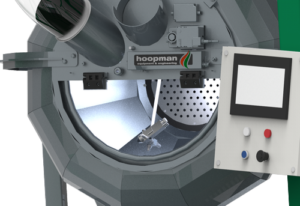

The HR600 is the most commonly used format rotary coaters. This is ideal for processes of medium to large seedlots/orders.

The HR600 seed coating capacity is, depending on seed/recipe, about 800-1200 litres seed per hour (based on a 45s batch time and a polymer/pesticide slurry application of 35 g/kg).

The HR600 is available in different types, ranging from complete manual control to a fully automated machine.

HR600 Semi – Setup with PLC, powderfeeder and liquid pump

Features:

◦ High speed coating

◦ High speed pelleting

◦ Easy to use and access

◦ Modular design (from manual to plug and play)

◦ 100% access via the top from the Center’s addition of fluid

◦ The spout of the door opens in the direction of rotation which makes for a fast export of the machine standard version E&E grey powder coat

◦ CE-European industry standard

◦ PLC machines are equipped with a modem for remote support

Capabilities:

Batch size: 20 l

Basic disinfection: 1600-3000 l/hr ** (15-30 seconds process time)

Film coat: 900-1200 l/hr ** (50-80 seconds process time)

Encrusting 250-500 l/hr * * (120-240 seconds process time)

* * capacity based on average values, depend greatly on actually process

Fill in the form below and a link to the PDF-file will be shown.

“High coatings capacity with ample process accessibility,

for processes of 800-13000 l/hr”

The HR1000 is highly suitable for medium production lines for both encrusting as film-coating. The HR-1000 may vary, depending on the desired Setup configured with multiple supply components such as fluids and/or powders.

The HR1000 can coat, depending on your recipe, about 2500-5500 litre seed per hour (based on 45s batch time and a polymer/pesticide mix of 35 g/kg).

The HR1000 is available in different types, ranging from complete manual control to fully automated machine. In addition, Hoopman equipment & engineering custom machines HR-1000.

Features:

◦ High speed coating

◦ High speed pelleting

◦ Easy to use and access

◦ Modular design (from manual to plug and play)

◦ 100% access via the top from the Center’s addition of fluid

◦ The spout of the door opens in the direction of rotation which makes for a fast export of the machine standard version e&e grey powder coat

◦ CE-European industry standard

◦ PLC machines are equipped with a modem for remote support

Fill in the form below and a link to the PDF-file will be shown.

“Easy, simple and quick change between different coating mixtures, that is the simplicity of our Smart Liquid Supply System”

With the SLSS you can easily, quickly and accurately process your liquids feeding to the coatings. Are you tired of making a mixture every single time? Then the SLSS is the perfect solution!

The SLSS doses each individual component directly from the container as it comes from your supplier. By a loss in weight system the SLSS always knows how much of each component is added and it is directly adjusted by means of an intelligent control.

Accuracy of dosing is extremely high: ± 0.3 gr dosing. The static mixer ensures that the components are well blended in your coating process. We can deliver the SLSS as Stand Alone or integrate into our coatings systems.

Features

- No pre-mixing of components in separate pre-mix tank

- No rest of slurry left after a coating order

- No exposure of the operator to various toxic components

- High accuracy by advanced control

- Easy input of coatings recipes

- Various different mixtures possible during 1 batch

- 0.3 gr dosing accuracy

- Various combinations/lineups possible

- Optional induction loop systems available for combining 1 base station with multiple supply unit

Ask for more info on this system so that we can set it up specifically to your wishes

Fill in the form below and a link to the PDF-file will be shown.

“Liquid Mixers from 90 up to 900 litre”

Each coating process requires a premixed slurry, to prevent this premixed slurry from de-mixing/settling it is important to have continuous movement. Hoopman delivers several standard sized liquid mixing systems. Each mixer is made with a cone bottom to be sure that it completely empties.

Each coating process requires a premixed slurry, to prevent this premixed slurry from de-mixing/settling it is important to have continuous movement. Hoopman delivers several standard sized liquid mixing systems. Each mixer is made with a cone bottom to be sure that it completely empties.

The mixers up to 300L are standard mounted on swivel wheels which makes it extremely easy to move around your plant. Each mixer is frequency controlled to let it have an intensive mixing when the liquid blend is made, and have it a less intensive, but slow movement to prevent de-mixing/settling.

We have several different standard sizes available, from 90 up to 900L. Ask us for more information.

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

“The best ‘pan pelleting’ equipment available; good seed-flow, even powder/liquid distribution and very operator friendly!”

For high value vegetable- or low volume stock seed, ‘pan pelleting’ is still a common or even the preferred choice.

“For higher loading and drying, yet easy to clean and gentle to the seeds!”

Features:

- Easy to clean

- No intensive mechanical stress your seeds

- Homogeneous liquid spray supply

- Efficient drying based on fluidised bed system

- Maximum seed temperature control during drying process

- Easy to operate by user-friendly HMI

- Complet process overview with 10″HMI

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

“The instrument of choice for fast and efficient testing of seed coatings recipes”

With minimal effort you can dose materials such as micronutriënts, colours, crop protection etc. precisely on seed.

Fast, easy and complete discharge of the coated seed because there are no door-hinges, liquid distribution plate etc.

Basic configuration with liquid disk in top cover part, with main disk on/off and speed regulation and setting of disposable syringes to quickly apply the slurry on the seed. Also powders can very easily be dosed onto the seeds.

The 2 built-in mixing blades will mix the seeds easy and quickly for a good mixture of seeds and applied products.

Ideal for product/protocol development and monitoring!

Features

- Stainless steel rotor and stator

- Control with on/off and speed rotor

- Coat batches up to 0.5l product

- Simple and easy emptying by rotation of the complete rotor/stator part

- Table-Top model, placing it on the table and connection via 230 v AC plug

- Standard with 2 mixing blades for optimal product mixing

- Standard 1~200-230vac / 50hz power supply (optionally other variants available)

Watch the video to see a demonstration of our latest version:

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

Hoopman provides different sizes powderfeeder.

One of the most widely used is the PF38, which is specially developed for our pan coater.

The blade in the powderfeeder ensures that the mixture of powder remains continuously mixed to prevent separation. A mortar then transports and doses with a homogeneous flow.

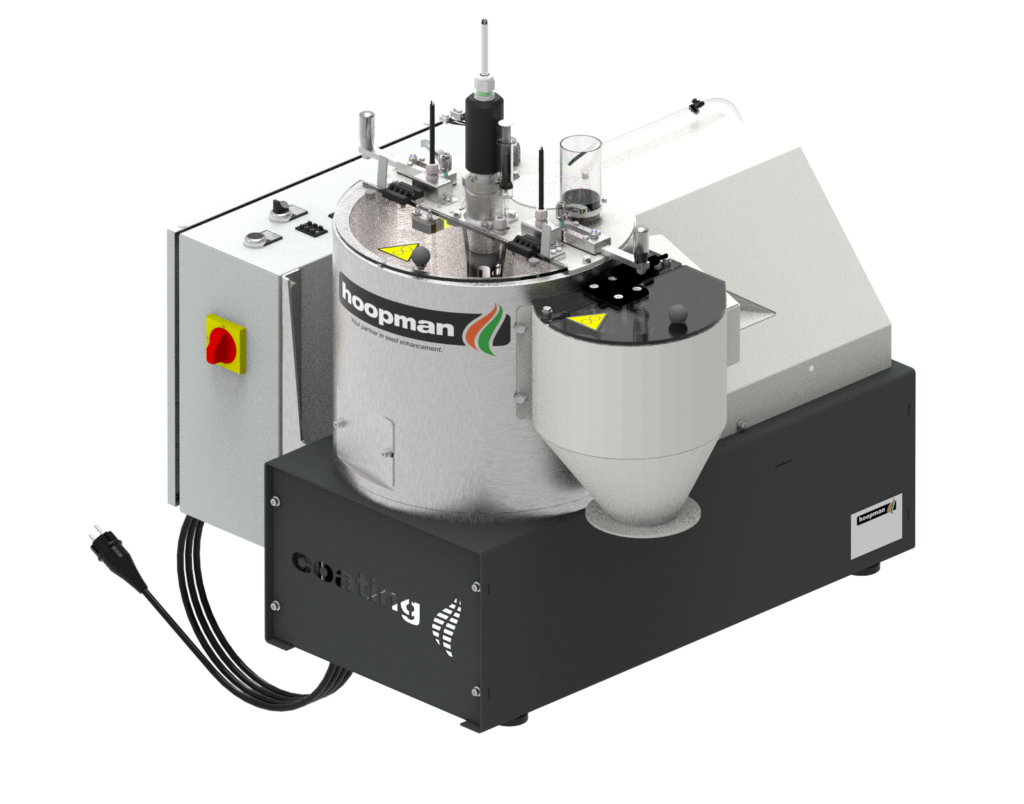

“Rotary Coater specially for small laboratory tests, to fully automated production!”

The HR350 is very suitable for small laboratory testing on “production” scale to test and/or to develop protocols for the larger production lines.

The fully automated version can do productions of up to 300 l/hr.

The HR350 is like the larger models equipped with our special design whereby the space between rotor and stator easy to adjust and quickly replaced in case of wear. The HR350 is available as “basic” but also as fully automated production machine.

|

|

HR350 Manual – Basic (table model) |

HR350 Advanced (PLC)

|

Features:

◦ From manual testing to fully automated productions

◦ Table-Top model, easy to use in laboratory environment

◦ Free access via lid for perfect view of the process

◦ Equipped with liquid distribution drive

◦ Optional with fluid pump

◦ Pneumatic Control door for easy unloading of seeds

◦ CE-Standard

Capacities:

Batch size: 4 l

Basic disinfection: 400-700 l/hr ** (15-30 seconds process time)

Film coat: 190-320 l/hr ** (50-80 seconds process time)

Encrusting 50-100 l/hr * * (120-240 seconds process time)

* * capacities based on common “averages”

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

“The powderfeeder for larger semi manual batches and automated encrusting/pelleting lines”

The PF45 is ideal to use with larger pelleting batches and/or automated pelleting- and encrusting lines. This powderfeeder has a capacity of about 0.3-4 l/min which can keep up with the with the necessary capacities for a typical HR800 or PC-XL process. In addition to the powder feeder can be provided with a host of alternative but standard transmissions whereby the capacity can be perfectly adjusted to your specific process.

All PF dosators are equipped with a mixing arm for prevention of separation/de-blending/bridging; this ensures that the different components cannot DE-mix during the pelleting and/or coatings process. For complete automatic systems there are loss in weight and/or pre-weigh systems available.

All PF dosators are equipped with a mixing arm for prevention of separation/de-blending/bridging; this ensures that the different components cannot DE-mix during the pelleting and/or coatings process. For complete automatic systems there are loss in weight and/or pre-weigh systems available.

Features

◦ Supplied with a plug for connection to a pancoater/rotary coater, so no external power supply necessary

◦ No bridges or separation of the product

◦ Constant powder dosage for a good and consistent metering and calibration

◦ Empties almost completely, and is therefore easy to clean

◦ Standard mounted on 4 swivel wheels for optimum mobility and flexible access to the coating pan.

In order to facilitate the filling of a powder feeder for the purpose of pelleting, we developed the PDBB Unit. (Powder Dosing Big-Bag)

This Unit can fill your powder feeder by weight. By placing big-bags of powder on the dedicated funnels, you can fill the powder feeder with two types of powder per unit.

The big-bags must be placed in a rack so that they can bulge out well. If the level does not allow you to have enough “hang”-height for the Big-Bags, you can use powder containers.

If you are interested in this system, please contact us.

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

“Conditioner designed to dedust and condition at high capacity’s”

The RFBC800 system is specially designed for dedusting and condition your treated seeds directly after treating. Because of its compact design it can be placed behind every kind of treating system already in place.

The RFBC800-7 conditioner has a capacity from 4-8t/hr (wheat seeds). We can also deliver a complete system including a rotary coater to have a complete automated coating/drying installation. Product Characteristics:

Product Characteristics:

- Adaptable to already used rotary coating systems

- Standard manual operated version

- PLC and Touch panel controlled system available

- Capacity varies depending on your rotary coating process, when you give us the needed capacity, humidity and process variables we can dimension the conditioner for you.

- Several air conditioning options available (depending on your process)

- Cooling section, with optional air cooling unit

- Different capacities/drying times available

- Ask us for more information about the system

Due to the variety of coating processes and humidity conditions of your specific business we configure the dryers based on our test equipment. Ask us for more information about a dryer for your specific process.

Fill in the form below and a link to the PDF-file will be shown.

Dust and chemical application on seed is an extremely sensitive issue in Europe and is emerging as a problem in other parts of the world.

Crop protection products registrations have been temporarily put on hold (with huge financial implications) due to the two major pesticide bee related incidents that have occurred within the last 10 years. This is the reason that Hoopman did rebuild their rotary fluid bed system to make “low cost” conditioning/de-dusting possible!

By adding a hoopman conditioner to your already in place treatment system you can easily de-dust and cure your treated seeds.

One of our smallest conditioners is the RFBC140-LAB, this conditioner has a capacity from 50 up to 150kg/hr (Depending on your conditioning time). By pushing ambient air through the seeds with a fluidised bed principle we have a good de-dusting and controllable and repeatable curing of your coating layer.

This small conditioner is perfect to develop protocols for bigger lines. We have several bigger machines available from 1 to 25t/hr. (Depending on the actual conditioning time required)

Advantages

- Conditioning and de-dusting in one run

- Cured film coating will allow products applied on the seeds to “hold better”

- Cured film coating has much better flow characteristics in both seed packing line and in planters

- Better control of application of products on seed

- Can be easily adapted to already in use film-coating, seed treatment system

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

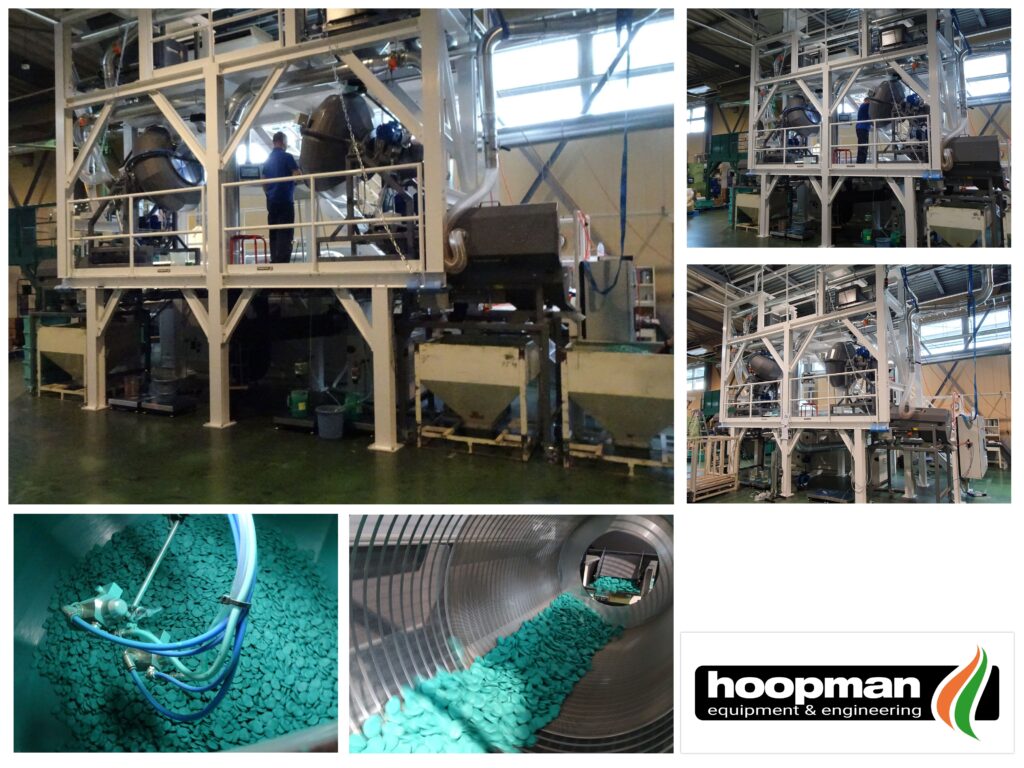

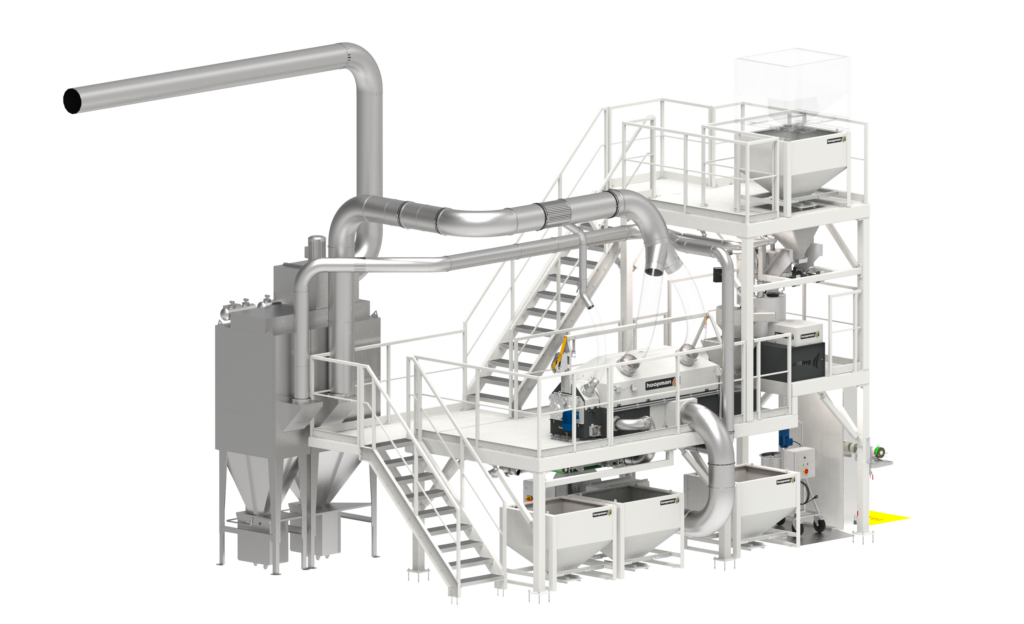

The last year we have delivered and build several projects world-wide. Below a small impression on what we have done. Beside deliverying individual equipment we are specialized in turn-key projects. From the engineering phase up to delivering, assembling comissioning and training!

Want to know more? Then contact our sales team!

In order to visually distinguish organic seed and non-chemically treated seed, Bejo has opted for an improved new yellowish colour coating for the organic seed.

This new durable coating consists of natural materials that break down completely. The coating also has a shorter drying time, which benefits the vitality of the seed and saves energy.

For this transition, Bejo has invested in a new production line with two Hoopman coating lines.

The HR350/HR600 coaters have been completely re-designed for durable operation and improved seed to seed distribution of liquids.

Hoopman has been able to develop and implement this diligent and successful project in very close collaboration with Bejo.

Are you also looking for a State of the Art coating line, where the seed is ready for packaging immediately after treatment?

Contact our sales team! They will be happy to inform you about the various options and all our other Seed Enhancement lines.

𝙄𝙣𝙣𝙤𝙫𝙖𝙩𝙞𝙤𝙣 𝙞𝙨 𝙥𝙖𝙧𝙩 𝙤𝙛 𝙤𝙪𝙧 𝙜𝙚𝙣𝙚𝙨

Hoopman has engineered and delivered several turn-key grass/alfalfa encrusting lines all over the world.

If you are looking for a flexible, high capacity and rely able encrusting systems.

Please contact our sales to know more.

Over the years we delivered high-capacity filmcoating equipment all over the world from very basic setups up till fully automated SLSS powered systems.

If you are looking for a modular setup with high throughput?

Contact our sales team to know more.

We have delivered turn-key mid-capacity filmcoating lines all over the world.

From very basic setups up till fully automated systems with SLSS and high-end air conditioning systems.

Hoopman can configure the lines completely to your spec an is able to deliver and install this systems turn-key!

Interested? Please contact our sales team.

In order to do small trails and/or even productions we have designed and delivered several HR350 based coating lines.

A HR350 automated system with a RFBD300 can mimic the production of our bigger lines.

But as small productions (up to 75-100kg/hr) can be done in this nice compact machine.

If you are looking for a system to help protocol development but also do small production quantities?

Please ask our sales team

For fragile seeds and/or high slurry loads we have delivered turn-key ICD systems from semi automatic up till complete automated lines.

The ICD has the advantage that it handles seed very gentle and is extremely easy to operate and clean.

Due to the multi step drying/coating option you can create high slurry load protocols.

If you are looking for a good solution to coat seeds such as cucumber/melon/beans, which are easily damaged by the rotary coating principle, please ask our sales team to inform you about the ICD.

Hoopman is a specialist in application machines for seeds. The latest development work resulted in two unique coating/drying systems. Since ICI’s development of the rotary coating machine there are many conventional seed coating machines replaced by this still recent pesticide application principle.

Our new development is, that we have created the opportunity to combine the extremely fast pesticide application possibilities of the rotary coater with an unique non vibrating fluidized bed dryer system.

We do not use the rotary coater for drying, because this strongly influences the capacity of the rotary coating system. For higher loading and seed damage risk (due to intense mixing in rotary coaters) we developed an ICD (integrated drying/coating) system. For more information see ICD. So we currently have two seed coating systems available.

Both systems are available as complete automatic coating and drying systems. All machines can be equipped with a touch-screen panel to support the operator to execute optimal and easy coating and drying processes. In addition, it is possible to easily save/retrieve recipes. All E&E coaters are designed in such a way, that they can do both Filmcoating, Encrusting and Pelleting processes.

“Simple straight- forward flow testing system”

The FT-Flowtester is a simple and straight forward system to test the difference between the flow before and after coating and/or drying/conditioning.

After placing seed in the hopper you can set the opening time of the valve. After pressing the green button the valve opens during the set time. You can put a holding bucket or container underneath the slide. This platform can be easily change in height, so several different containers can be used.

When you separately weigh the dosed amount in the container/bucket you can see if the flow characteristics are changed.

Watch the video to see a demonstration:

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

The specially designed Hoopman seed containers are made without any sharp corners. Due to this design the seeds cannot get stuck in the container and a complete emptying is secured.

A special designed slide valve, which is easy to operate, is mounted to the bottom of the seed container. With this valve you can easily open/close the container. Even during the emptying.

We can deliver this containers in several standard dimensions, but optionally we can build them based on customer request.

- No sharp edges/corners where seed could get stuck

- Easy to operate and completely closed valve

- Easy stackable

- Flexible seed outlet, to dose into standard hoppers without risk of

Infosheet – PDF

Fill in the form below and a link to the PDF-file will be shown.

SE-60L Single Bucket Elevator

To make the filling of the CSS-400 Sieve System more simple, we have the Seed Lift available. This simple single bucket elevator can be easily filled with seeds on a low level. It is even easy to empty our standard drying containers in its hopper.

Optionally we have a Seed Lot Splitter available which can be mounted on the frame of the SE-60L. With this system it is possible to split one lot in 4 similar smaller lots (See figure 1).

The seed lift works very simple, and has an automatic valve which will be opened by the system when the hopper is at the emptying place. You press the up button on the control, and the seeds will be transported from the filling position into the emptying position above the CSS-400 or Seed Lot Splitter, and the door of the hopper will be opened. When you press down, the valve will be closed and the Hopper goes to its filling position again.

Infosheet – PDF

For more information, please contact us or fill in the form below, a link to the PDF-file will be shown.

“The coater for 1500-7000 l/hr productions,

from manual to fully automated”

The HR800 is highly suitable for medium production lines for both encrusting as film-coating. The HR800 may be varied, depending on the desired Setup configured with multiple supply components such as liquids and/or powders. The HR800 can coat, depending on your recipe, about 800-1200 litres seed per hour (based on 45s batch time and a polymer/pesticide mix of 35 g/kg).

The HR800 is available in different types, ranging from complete manual version to fully automated machine. In addition, Hoopman equipment & engineering can custom build HR800 machine/installations.

Features:

◦ High speed coating

◦ High speed pelleting

◦ Easy to use and access

◦ Modular design (from manual to plug and play)

◦ 100% access through the top from the Center’s addition of fluid

◦ The spout of the door opens in the direction of rotation which makes for a fast export of the machine standard version e&e grey powder coat

◦ CE-European industry standard ◦ PLC machines are equipped with a modem for remote support

Fill in the form below and a link to the PDF-file will be shown.

Belt elevator for seeds

The is a new small belt conveyor to transport seeds to a production system when there is not enough height to do it by gravity.

The is an open, easy to clean belt system which can be used for several seeds.

The can be made in several sizes and slopes, to fit almost every required height/length issue. If you are interested in this system, please let us know.