Meet us at ISF World Seed Congress 2024

The annual World Seed Congress will be held in our home country, The Netherlands. It is taking place from 27 May to 29 May 2024.

The ISF World Seed Congress is an opportunity to bring people in the global seed sector from across the globe together to explore new ideas and share innovative solutions.

Hoopman, your partner in seed enhancement

Within Hoopman there exists a tremendous amount of know how and experience in equipment manufacturing and engineering. The expertise regarding seed processing already exists for more then 50 years. This has resulted in a set of highly appreciated unique tools for seed treatment:

- Disinfection / priming

- Sorting

- Coating

- Drying / conditioning

Beside delivering individual equipment we are also specialized in Turn-Key projects. From the engineering phase up to delivery, assembling, commissioning and training. Meet us at ISF 2024 and learn more about our range of equipment and our engineering skills.

Let’s meet!

Schedule your meeting with Rianne or Marieke by picking a day and time here >>

They look forward welcoming you and answer your questions at our booth number 3.4.

You can meet Jan Willem at trading table number 44.

We look forward to seeing you in Rotterdam!

Venue ISF 2024:

Rotterdam Ahoy

Ahoyweg 10

3084 BA Rotterdam

Opening hours ISF Exhibition:

- Monday, 27 May 11.00 – 18.00

- Tuesday, 28 May 8.00 – 18.00

- Wednesday, 29 May 8.00 – 18.00

***************************************************************************************************************************************************

Saatguthandelstag Magdeburg 2024 – Germany

The Saatguthandelstag will take place in Magdeburg – Germany on 14 and 15 May. Field seed traders, multipliers and plant breeders from all over Germany and neighbouring EU countries are represented at this business conference.

Jan Willem and Julia Hoopman are looking forward meeting you at Saatguthandelstag. If you are not present in Magdeburg, we will be happy to schedule an appointment or an (online) meeting at another moment, please send an email to info@hoopman-equipment.nl.

***************************************************************************************************************************************************

Modified opening hours due to the holidays

Due to the upcoming holidays, our company will be closed on the following days:

- Good Friday: Friday 29 March

- Easter: Monday 1 April

- Ascension Day: Thursday 9 May and Friday 10 May

- Pentecost: Monday 20 May

If urgent contact is required, please use our Service/Parts button on our website. This mailbox is checked regularly, and we will get back to you soon. Please note that the response time can be a little longer than usual.

We wish everyone happy holidays!

***************************************************************************************************************************************************

Limited accessibility around the holidays.

Due to the holidays, our company will be closed from the 22nd of December to January 2nd.

If urgent contact is required, please use our Service/Parts button on our website. This mailbox is checked regularly, and we will get back to you soon. Please note that the response time can be a little longer than usual.

We would like to thank you for your cooperation and trust in the past year!

The Hoopman team wishes you happy holidays and a successful and healthy 2024!

***************************************************************************************************************************************************

Saatguthandelstag Magdeburg 2023 – Germany

The Saatguthandelstag will take place in Magdeburg – Germany on 9 and 10 May. Field seed traders, multipliers and plant breeders from all over Germany and neighbouring EU countries are represented at this business conference.

Jan Willem Hoopman is looking forward meeting you at Saatguthandelstag. If you are not present in Magdeburg, we will be happy to schedule an appointment of an (online) meeting at another moment, please send an email to info@hoopman-equipment.nl.

***************************************************************************************************************************************************

Meet us at ISF World Seed Congress 2023 – South Africa

The annual World Seed Congress will be held in Cape Town at the International Convention Center. It is taking place from 5 June to 7 June 2023.

The World Seed Congress is an opportunity to bring people in the global seed sector from across the globe together to explore new ideas and share innovative solutions.

You are welcome to visit our booth, number 719. We look forward to seeing you in Cape Town!

***************************************************************************************************************************************************

April 2023

Modified opening hours due to the holidays

Due to the upcoming holidays, our company will be closed on the following days:

- King’s Day: Thursday 27 April

- Ascension Day: Thursday 18 May and Friday 19 May

- Pentecost: Monday 29 May

We advise you to order your parts on time by filling in the service/parts form. Please note that the response and delivery times are a little longer than usual due to the holidays.

We wish everyone happy holidays!

***************************************************************************************************************************************************

December 2022

Our colleagues from project engineering and operation specialism are travelling across the ocean to support one of our US customer’s (Syngenta) with the commissioning and training of a full automatic film coating line.

November 2022

“𝘞𝘪𝘵𝘩 𝘨𝘳𝘦𝘢𝘵 𝘱𝘭𝘦𝘢𝘴𝘶𝘳𝘦 𝘢𝘯𝘥 𝘴𝘢𝘵𝘪𝘴𝘧𝘢𝘤𝘵𝘪𝘰𝘯 𝘸𝘦 𝘢𝘳𝘦 𝘭𝘰𝘰𝘬𝘪𝘯𝘨 𝘣𝘢𝘤𝘬 𝘵𝘰 𝘰𝘶𝘳 𝘣𝘶𝘴𝘪𝘯𝘦𝘴𝘴 𝘵𝘳𝘪𝘱 𝘵𝘰 𝘈𝘴𝘪𝘢.

𝘞𝘦 𝘱𝘢𝘳𝘵𝘪𝘤𝘪𝘱𝘢𝘵𝘦𝘥 𝘪𝘯 𝘵𝘩𝘦 𝘈𝘗𝘚𝘈 𝘤𝘰𝘯𝘨𝘳𝘦𝘴𝘴 𝘪𝘯 𝘉𝘢𝘯𝘨𝘬𝘰𝘬 (𝘛𝘩𝘢𝘪𝘭𝘢𝘯𝘥) 𝘢𝘯𝘥 𝘩𝘢𝘥 𝘵𝘩𝘦 𝘰𝘱𝘱𝘰𝘳𝘵𝘶𝘯𝘪𝘵𝘺 𝘵𝘰 𝘮𝘦𝘦𝘵 𝘦𝘹𝘪𝘴𝘵𝘪𝘯𝘨 𝘢𝘯𝘥 𝘮𝘢𝘯𝘺 𝘯𝘦𝘸 𝘳𝘦𝘭𝘢𝘵𝘪𝘰𝘯𝘴.

𝘛𝘩𝘦𝘯 𝘸𝘦 𝘷𝘪𝘴𝘪𝘵𝘦𝘥 𝘛𝘢𝘪𝘸𝘢𝘯 𝘢𝘯𝘥 𝘑𝘢𝘱𝘢𝘯 𝘢𝘯𝘥 𝘸𝘦𝘳𝘦 𝘪𝘮𝘱𝘳𝘦𝘴𝘴𝘦𝘥 𝘣𝘺 𝘢𝘭𝘭 𝘵𝘩𝘦 𝘮𝘦𝘦𝘵𝘪𝘯𝘨𝘴 𝘢𝘯𝘥 𝘵𝘩𝘦 𝘸𝘢𝘳𝘮 𝘸𝘦𝘭𝘤𝘰𝘮𝘦.

𝘞𝘦 𝘵𝘳𝘢𝘷𝘦𝘭 𝘣𝘢𝘤𝘬 𝘵𝘰 𝘵𝘩𝘦 𝘕𝘦𝘵𝘩𝘦𝘳𝘭𝘢𝘯𝘥𝘴 𝘬𝘯𝘰𝘸𝘪𝘯𝘨 𝘵𝘩𝘢𝘵 𝘏𝘰𝘰𝘱𝘮𝘢𝘯 𝘪𝘴 𝘢𝘯𝘥 𝘸𝘪𝘭𝘭 𝘣𝘦 𝘢 𝘷𝘢𝘭𝘶𝘢𝘣𝘭𝘦 𝘱𝘢𝘳𝘵𝘯𝘦𝘳 𝘧𝘰𝘳 𝘴𝘦𝘦𝘥 𝘦𝘯𝘩𝘢𝘯𝘤𝘦𝘮𝘦𝘯𝘵 𝘪𝘯 𝘈𝘴𝘪𝘢 𝘢𝘯𝘥 𝘖𝘤𝘦𝘢𝘯𝘪𝘢.

𝘐𝘵 𝘸𝘢𝘴 𝘰𝘷𝘦𝘳𝘸𝘩𝘦𝘭𝘮𝘪𝘯𝘨, 𝘵𝘩𝘢𝘯𝘬 𝘺𝘰𝘶 𝘷𝘦𝘳𝘺 𝘮𝘶𝘤𝘩!

𝘔𝘢𝘳𝘪𝘦𝘬𝘦 𝘷𝘢𝘯 𝘎𝘰𝘳𝘴𝘴𝘦𝘭 & 𝘙𝘪𝘢𝘯𝘯𝘦 𝘒𝘳𝘶𝘪𝘴𝘴𝘦𝘭𝘣𝘳𝘪𝘯𝘬 ”

Oktober 2022

September 2022

We are pleased to invite you at our booth during Seed meets Technology 2022 in Zwaagdijk (NL).

At SMT we show some of our stand alone seed enhancement equipment and inform you about our next step developments in Steam Seed Treatment and Liquid Matrix / Drum Treatments.

Let’s meet at our booth 24 and/or visit our Company Presentation by Jan Willem Hoopman in our meeting room on Tuesday afternoon! (14.00 – 14.30h or 15.00-15.30h).

Send an email to info@hoopman-equipment.nl for reservation.

May 2022

What a wonderful start of the International Seed Federation Congress 2022 in Barcelona!

Together with Agro Business Solutions we welcomed some valued guests on our rooftop Pre-party. 🥂

Dear guest thank you for being there and looking forward to meeting all our relations during the congress.

February 2022

𝗪𝗼𝗿𝗸 𝗶𝗻 𝗽𝗿𝗼𝗴𝗿𝗲𝘀𝘀!

Currently our team is assembling and commissioning an impressive 𝗜𝗥𝗖𝗗 𝗖𝗼𝗮𝘁𝗶𝗻𝗴 𝗣𝗹𝗮𝗻𝘁 at TECHNISEM in France

(IRCD = Integrated Rotary Coating & Drying)

We thank Technisem for the trust and pleasant cooperation.

***************************************************************************************************************************************************

December 2021

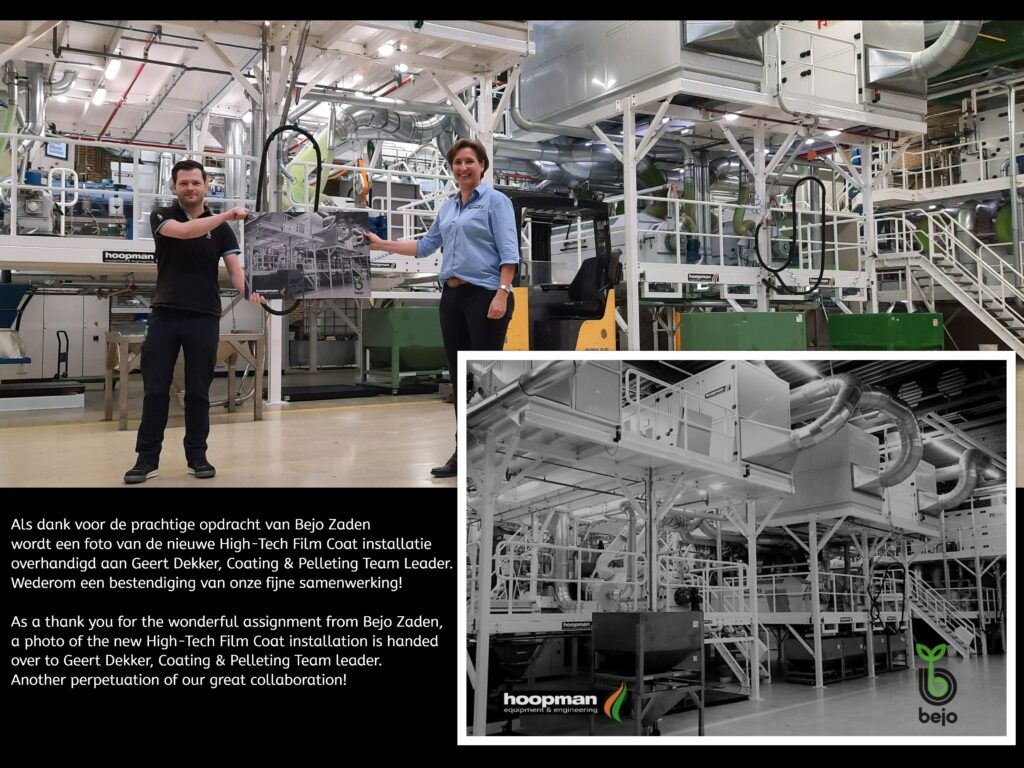

As a thank you for the wonderful assignment from Bejo Zaden, a photo of the new 𝗛𝗶𝗴𝗵-𝗧𝗲𝗰𝗵 𝗙𝗶𝗹𝗺 𝗖𝗼𝗮𝘁 𝗶𝗻𝘀𝘁𝗮𝗹𝗹𝗮𝘁𝗶𝗼𝗻 is handed over

to Geert Dekker, Coating & Pelleting Team Leader.

Another perpetuation of our great collaboration!

***************************************************************************************************************************************************

November 2021

De samenwerking van de bedrijven Joordens en Hoopman heeft al aanknopingspunten uit de vijftiger jaren. De stoppelknol was de aanzet voor Hoopman om de Knollenplukker in productie te nemen en naast de stoppelknol legde Joordens toen al de basis voor wat wereldwijd misschien wel de meest succesvolle voerderbiet is: de ‘Brigadier’!

Om stil te staan bij het 100-jarig bestaan van Joordens Zaden BV overhandigt Jan Willem Hoopman de “lichtgevende Brigadier” aan John Smolenaars

***************************************************************************************************************************************************

November 2021

Hoopman equipment & engineering is a specialist in custom made turn-key projects.

Currently our team is commissioning an impressive Full Automated Coating Line at a highly valued customer!

***************************************************************************************************************************************************

September/October 2021

It was a great pleasure to finally meet you in real life during Seed Meets Technology, Euroseeds and/or BVO Saatguthandelstag

|

|

|

| Seed Meets Technology – Zwaagdijk (NL) | Euroseeds – Praag (CZ) | BVO Saatguthandelstag – Magdeburg (D) |

***************************************************************************************************************************************************

August 2021

Enza Zaden 𝗚𝗲𝗿𝗺𝗮𝗻𝘆 is now the proud owner of a 𝗩𝗖𝗦𝟲𝟬𝟬-𝟯 𝗩𝗶𝗯𝗿𝗮𝘁𝗶𝗻𝗴 𝗖𝗮𝗹𝗶𝗯𝗿𝗮𝘁𝗶𝗼𝗻 𝗦𝘆𝘀𝘁𝗲𝗺.

Because they work with special seeds, the sieving parts needed to be manufactured in Stainless Steel.

What a great result and happy customer!

Want to know more, contact us at info@hoopman-equipment.nl

***************************************************************************************************************************************************

July 2021

This month we transported 7 𝐂𝐃𝐒 𝐂𝐚𝐫𝐭 𝐃𝐫𝐲𝐢𝐧𝐠 𝐒𝐲𝐬𝐭𝐞𝐦𝐬 (5 pieces for Kenya and 2 pieces for Zimbabwe)

This flexible and easy to use drying system is specially designed for drying of non-threshed corn earns or other non threshed seed.

However it can also be used for static drying of a multitude of different, smaller seed lots in mesh bags.

You simply connect a moveable stack of containers to the machine and start the drying process.

Want to know more? Contact our sales team!

***************************************************************************************************************************************************

June 2021

Our engineers and technicians are currently testing and fine-tuning an impressive 𝗕𝗶𝗼𝗥𝗶𝗻𝘀𝗲 treatment station.

This special rinsing station is designed to rinse/treat seeds with various protocols such as ‘hot water treatment’.

After this treatment, you can place the box in a fast fluid bed dryer to dry back the seeds to the requested absolute moisture.

Want to know more about our Disinfection program?

Contact our sales team, we have several options available and can configure this system based on your specs and volumes!

|

|

***************************************************************************************************************************************************

May 2021

𝙉𝙚𝙬 𝘽𝙄𝙊 𝙘𝙤𝙖𝙩𝙞𝙣𝙜 𝙡𝙞𝙣𝙚𝙨 𝙛𝙤𝙧 𝘽𝙚𝙟𝙤

In order to visually distinguish organic seed and non-chemically treated seed, Bejo has opted for an improved new yellowish colour coating for the organic seed.

This new durable coating consists of natural materials that break down completely. The coating also has a shorter drying time, which benefits the vitality of the seed and saves energy.

For this transition, Bejo has invested in a new production line with two Hoopman e&e coating lines.

The HR350/HR600 coaters have been completely re-designed for durable operation and improved seed to seed distribution of liquids.

Hoopman equipment & engineering has been able to develop and implement this diligent and successful project in very close collaboration with Bejo.

|

|

Are you also looking for a State of the Art coating line, where the seed is ready for packaging immediately after treatment?

Contact our sales team! They will be happy to inform you about the various options and all our other Seed Enhancement lines.

𝙄𝙣𝙣𝙤𝙫𝙖𝙩𝙞𝙤𝙣 𝙞𝙨 𝙥𝙖𝙧𝙩 𝙤𝙛 𝙤𝙪𝙧 𝙜𝙚𝙣𝙚𝙨

***************************************************************************************************************************************************

March 2021

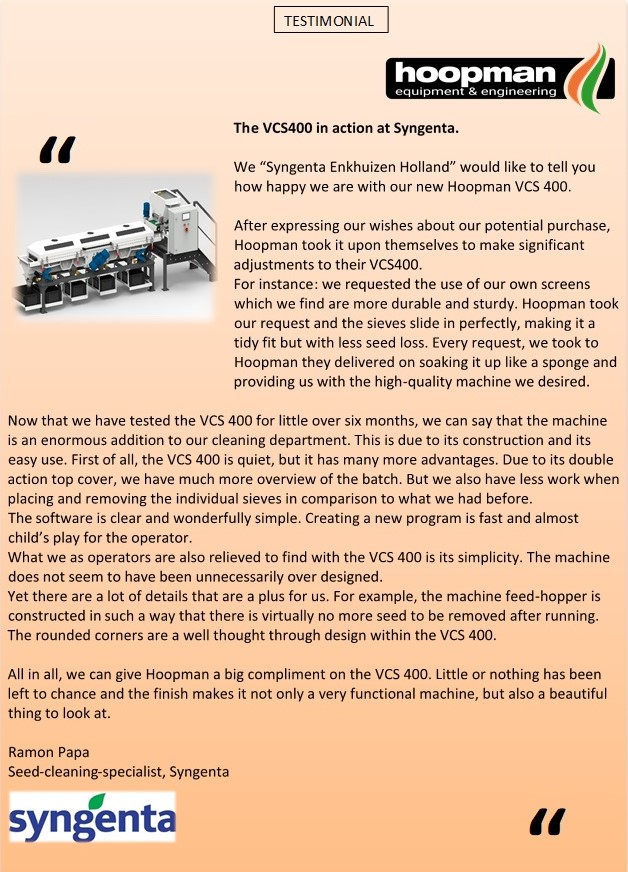

With great pleasure (and pride) we received these kind words from a highly valued customer:

***************************************************************************************************************************************************

March 2021

Despite the Covid-19 limitations our sales and engineers work online with our customers. Currently we are working together with a client across the Atlantic. With online help from our expert engineers a BioRinse Treatment station is set up and commissioned.

***************************************************************************************************************************************************

Oktober 2020:

At the end of October we delivered our Priming Cabinet to our customer Innoveins.

This multifunctional priming system is perfect for developing liquid matrix priming protocols.

With this system you are able to test 10 different priming receipes to improve a specific batch or seed or to develop a complete new priming recipe.

*****************************************************************************************************************************************************

Oktober 2020:

Despite the Covid-19 our factory is running at full speed in order to serve our customers around the world. This complete IRCD800 line is ready and packed to be transported across the ocean.

With this new line, which is pre-connected and tested, our customer can start to produce directly after installing.

Hoopman equipment & engineering is your partner for full automated film coating and encrusting lines!

Interested? Ask our sales team Marieke van Gorssel and Rianne Kruisselbrink for more information.

*****************************************************************************************************************************************************

September 2020:

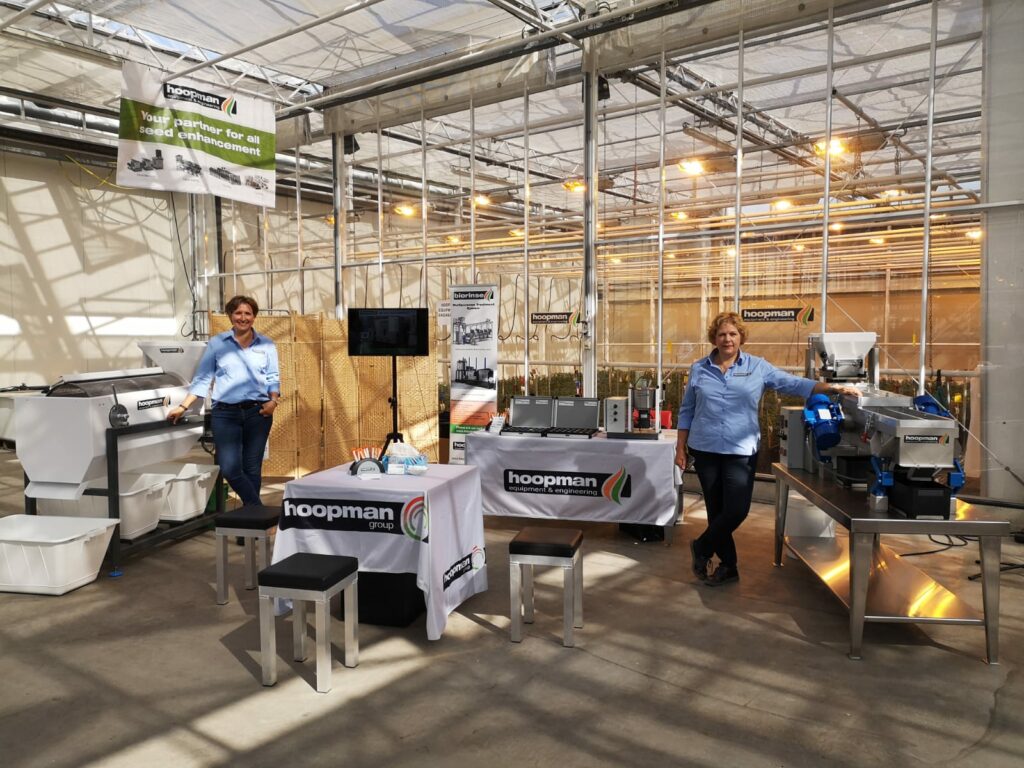

Taking all Covid-19 measures into account, we were present during the Zaadtechniek Demonstratiedagen at Proeftuin Zwaagdijk.

Our sales team: Rianne Kruisselbrink and Marieke van Gorssel

*****************************************************************************************************************************************************

September 2020:

We are proud to announce the delivery of the new ‘Bio Coating line’ at Bejo Zaden.

The first production of organic seed with new coating equipment has started.

We thank Bejo Zaden for the great opportunity to deliver this great piece of equipment and wish them the best of luck!

Click here

*****************************************************************************************************************************************************

July 2020:

Last month we deliverd 35 bottom unloading containers to Bejo Zaden. They use these containers for internal transport between different processes.

We can produce them in different colours and sizes according to your needs! And of course with our high end quality and finish.

Interested? Please contact our sales team!

*****************************************************************************************************************************************************

June 2020:

𝙁𝙪𝙩𝙪𝙧𝙚-𝙥𝙧𝙤𝙤𝙛 𝙬𝙞𝙩𝙝 𝙩𝙝𝙚 𝙃𝙤𝙤𝙥𝙢𝙖𝙣 𝘾𝙖𝙧𝙩 𝘿𝙧𝙮𝙞𝙣𝙜 𝙎𝙮𝙨𝙩𝙚𝙢!

This flexible and easy to use drying system is specially designed for drying of non-threshed corn earns or other non threshed seed.

However it can also be used for static drying of a multitude of different, smaller seed lots in mesh bags.

You simply connect a moveable stack of containers to the machine and start the drying process.

* 𝗘𝗮𝘀𝘆 𝘁𝗼 𝘂𝘀𝗲; moveable Dryer with a plug and play static Cart Drying System

* 𝗘𝗮𝘀𝘆 𝗮𝗻𝗱 𝘀𝗮𝗳𝗲 𝘁𝗼 𝘀𝘁𝗼𝗿𝗲 𝘄𝗵𝗲𝗻 𝗻𝗼𝘁 𝗶𝗻 𝘂𝘀𝗲; takes hardly any space and the drying boxes can be logistically used in the off-season

* 𝗘𝗹𝗲𝗰𝘁𝗿𝗶𝗰 𝗳𝗮𝗻 𝗮𝗻𝗱 𝗵𝗲𝗮𝘁𝗶𝗻𝗴; easy to operate without the use of gas/oil; works always; no checking of (smelly) burners prior to the season

* 𝗘𝘅𝘁𝗿𝗲𝗺𝗲𝗹𝘆 𝗾𝘂𝗶𝗲𝘁; can be used in same work space where the crops are coming in/being processed/packed or even for drying after CPP-application

* 𝗩𝗲𝗿𝘆 𝗳𝗮𝘀𝘁 𝗥.𝗢.𝗜.; it is low cost per drying capacity/handling-box; divers drying jobs can be done outside of the ‘counter season rush’

*****************************************************************************************************************************************************

March 2020:

In this period where Covid-19 is the talk of the town, we want to share some exited news with you!

As from Monday our sales team will be expanded by Rianne Kruisselbrink where she will take care of the Customer Service.

She will contribute to take the customer experiences to an even higher level!

*****************************************************************************************************************************************************

March 2020:

On March 11th and 12th 2020, in the city of Amsterdam the Agri Seed Treatment Conference was organized. The event was hosted in the NH Amsterdam Center hotel, close to the Rijks Museum. Unfortunately, due to intensification of governmental Corona-measure, not all delegates were able to attent the Conference. Nevertheless, 90% of the speakers could make it and around 75% of the delegates arrived safely in Amsterdam listening to speakers from all over the world. One of the speakers was Jan Willem Hoopman, owner of the Hoopman Group. His presentation tried to give a realistic insight in: ‘Future Proof Seed Enhancement Systems’.

*****************************************************************************************************************************************************

February 2020:

Today the 2nd shipment for a complete BioRinse plant was picked up for transport. Soon to be built-up at one of our clients. Do you want to know more about this large sized treatment stations?

*****************************************************************************************************************************************************

December 2019:

The last few weeks we installed two nice coating machines in France. One fully automated line including drying and one coating line with separate dryer.

Both equipped with state of the art weigh-out liquid dosing and high efficient air conditioning systems.

*****************************************************************************************************************************************************

November 2019:

In the next few weeks we will install several coating equipment at a customer in France. Today the first truck departed, we look forward to install this state-of-the art Seed Coating equipment!

*****************************************************************************************************************************************************

1th renewed HR-1000 has been delivered!

In 2008 Dutch Seed Group Int. in Hem started with one HR-600 to deal with their coating production. The last few years their coating production increased which resulted in adding an extra HR-800 in 2016. But as the production kept increasing, they recently bought an renewed HR-1000 to replace their 10 year old HR-600 coater.

HR-800 and HR-1000 on one platform, easy and high capacity box > box filmcoating

This renewed HR-1000 gives Dutch Seed Group Int. the capability to do batches of 100-120L of seeds in 1-2 minutes. One of the newest designs on these HR-1000 is the outlet shape. This new shape has been developed in cooperation with one of our customers and we are currently implementing this on all our Rotary Coating machines. The round shape of the outlet gives less damage to the seeds and ensures smooth emptying of the coating machine.

Do you want to know more about our HR-1000 and/or one of the other sizes? Then please contact us at info@hoopman-equipment.nl

*************************************************************************************************************************************************

The Wire Weaving Dinxperlo connection with Hoopman equipment & engineering

Wire Weaving Dinxperlo interviewed our colleague Mark Bretveld about their relation with our seed industry.

Read the entire article here:

*************************************************************************************************************************************************

Recently installed in the USA:

An Integrated Rotary Coating Drying System, fast and easy continuous coating and drying your seed!

Curious? Read more about this system on this page.

************************************************************************************************************************************************

Ready for ISF World Seed Congress 2024

We are ready to meet you at the annual World Seed Congress in Rotterdam, The Netherlands. It is taking place from 27 May to 29 May 2024. The ISF World Seed Congress is an opportunity to bring people in the global seed sector from across the globe together to explore new ideas and share innovative solutions. Hoopman, Read More

[:nl]Lees verder[:en]Read moreSaatguthandelstag Magdeburg 2024 – Germany

The Saatguthandelstag will take place in Magdeburg – Germany on 14 and 15 May. Field seed traders, multipliers and plant breeders from all over Germany and neighbouring EU countries are represented at this business conference. Jan Willem and Julia Hoopman are looking forward meeting you at Saatguthandelstag. If you are not present in Magdeburg, we Read More

[:nl]Lees verder[:en]Read moreMeet us at ISF World Seed Congress 2024

The annual World Seed Congress will be held in our home country, The Netherlands. It is taking place from 27 May to 29 May 2024. The ISF World Seed Congress is an opportunity to bring people in the global seed sector from across the globe together to explore new ideas and share innovative solutions. Hoopman, Read More

[:nl]Lees verder[:en]Read moreModified opening hours due to the holidays

Due to the upcoming holidays, our company will be closed on the following days: Good Friday: Friday 29 March Easter: Monday 1 April Ascension Day: Thursday 9 May and Friday 10 May Pentecost: Monday 20 May If urgent contact is required, please use our Service/Parts button on our website. This mailbox is checked regularly, and we will Read More

[:nl]Lees verder[:en]Read moreASTA’S 63rd Vegetable & Flower Seed Conference

ASTA’s Vegetable and Flower Seed Conference offers unrivaled networking and educational opportunities for the global vegetable and flower seed industry. This event continues to be America’s fastest growing seed industry conference. Let’s meet: Our specialist Marieke van Gorssel will be present during the Conference from 27 January until 29 January. She will be pleased to Read More

[:nl]Lees verder[:en]Read moreLimited accessibility around the holidays

Due to the holidays, our company will be closed from the 22nd of December to January 2nd. If urgent contact is required, please use our Service/Parts button on our website. This mailbox is checked regularly, and we will get back to you soon. Please note that the response time can be a little longer than usual. We Read More

[:nl]Lees verder[:en]Read moreHoopman at Euroseeds 2023

We are attending the Euroseeds Congress and you are very welcome at our booth, number 36. The Euroseeds congress will be held from 15 to 18 October, in St Julians on Malta. At Euroseeds you’ll find participants and exhibitors from countries around the world. There will be a buzzing atmosphere of professional exchange, showcases of Read More

[:nl]Lees verder[:en]Read moreSeed Meets Technology 2023

We would like to invite you to meet us during Seed Meets Technology in Zwaagdijk-Oost, the Netherlands. You can find us on booth number 22. Seed Meets Technology will take place from 26 to 28 September. An event where the focus is on innovative seed technology, variety assortment and adding value to horticultural seed. The Read More

[:nl]Lees verder[:en]Read moreSaatguthandelstag Magdeburg 2023 – Germany

The Saatguthandelstag will take place in Magdeburg – Germany on 9 and 10 May. Field seed traders, multipliers and plant breeders from all over Germany and neighbouring EU countries are represented at this business conference. Jan Willem Hoopman is looking forward meeting you at Saatguthandelstag. If you are not present in Magdeburg, we will be Read More

[:nl]Lees verder[:en]Read moreMeet us at ISF World Seed Congress 2023 – South Africa

The annual World Seed Congress will be held in Cape Town at the International Convention Center. It is taking place from 5 June to 7 June 2023. The World Seed Congress is an opportunity to bring people in the global seed sector from across the globe together to explore new ideas and share innovative solutions. Read More

[:nl]Lees verder[:en]Read moreModified opening hours due to the holidays

Due to the upcoming holidays, our company will be closed on the following days: King’s Day: Thursday 27 April Ascension Day: Thursday 18 May and Friday 19 May Pentecost: Monday 29 May We advise you to order your parts on time by filling in the service/parts form. Please note that the response and delivery times Read More

[:nl]Lees verder[:en]Read moreThank you Asia!

“𝘞𝘪𝘵𝘩 𝘨𝘳𝘦𝘢𝘵 𝘱𝘭𝘦𝘢𝘴𝘶𝘳𝘦 𝘢𝘯𝘥 𝘴𝘢𝘵𝘪𝘴𝘧𝘢𝘤𝘵𝘪𝘰𝘯 𝘸𝘦 𝘢𝘳𝘦 𝘭𝘰𝘰𝘬𝘪𝘯𝘨 𝘣𝘢𝘤𝘬 𝘵𝘰 𝘰𝘶𝘳 𝘣𝘶𝘴𝘪𝘯𝘦𝘴𝘴 𝘵𝘳𝘪𝘱 𝘵𝘰 𝘈𝘴𝘪𝘢. 𝘞𝘦 𝘱𝘢𝘳𝘵𝘪𝘤𝘪𝘱𝘢𝘵𝘦𝘥 𝘪𝘯 𝘵𝘩𝘦 𝘈𝘗𝘚𝘈 𝘤𝘰𝘯𝘨𝘳𝘦𝘴𝘴 𝘪𝘯 𝘉𝘢𝘯𝘨𝘬𝘰𝘬 (𝘛𝘩𝘢𝘪𝘭𝘢𝘯𝘥) 𝘢𝘯𝘥 𝘩𝘢𝘥 𝘵𝘩𝘦 𝘰𝘱𝘱𝘰𝘳𝘵𝘶𝘯𝘪𝘵𝘺 𝘵𝘰 𝘮𝘦𝘦𝘵 𝘦𝘹𝘪𝘴𝘵𝘪𝘯𝘨 𝘢𝘯𝘥 𝘮𝘢𝘯𝘺 𝘯𝘦𝘸 𝘳𝘦𝘭𝘢𝘵𝘪𝘰𝘯𝘴. 𝘛𝘩𝘦𝘯 𝘸𝘦 𝘷𝘪𝘴𝘪𝘵𝘦𝘥 𝘛𝘢𝘪𝘸𝘢𝘯 𝘢𝘯𝘥 𝘑𝘢𝘱𝘢𝘯 𝘢𝘯𝘥 𝘸𝘦𝘳𝘦 𝘪𝘮𝘱𝘳𝘦𝘴𝘴𝘦𝘥 𝘣𝘺 𝘢𝘭𝘭 𝘵𝘩𝘦 𝘮𝘦𝘦𝘵𝘪𝘯𝘨𝘴 𝘢𝘯𝘥 𝘵𝘩𝘦 𝘸𝘢𝘳𝘮 𝘸𝘦𝘭𝘤𝘰𝘮𝘦. 𝘞𝘦 𝘵𝘳𝘢𝘷𝘦𝘭 𝘣𝘢𝘤𝘬 Read More

[:nl]Lees verder[:en]Read more❗️🔧𝗦𝗲𝗿𝘃𝗶𝗰𝗲/𝗣𝗮𝗿𝘁𝘀 🔧❗️

Our website has a new function – 𝘁𝗵𝗲 𝗦𝗲𝗿𝘃𝗶𝗰𝗲/𝗣𝗮𝗿𝘁𝘀 𝗯𝘂𝘁𝘁𝗼𝗻! By adding this new functionality we have upgraded our service/aftersales/parts request system. We kindly ask our customers to use this new tool when requiring service. The simple form helps you to provide the right information straight away and ensures a quick follow up on your Read More

[:nl]Lees verder[:en]Read moreISF 2022 Barcelona – Hoopman e&e + ABS rooftop Pre-party

What a wonderful start of the International Seed Federation Congress 2022 in Barcelona! Together with Agro Business Solutions we welcomed some valued guests on our rooftop Pre-party. 🥂 Dear guest thank you for being there and looking forward to meeting all our relations during the congress.

[:nl]Lees verder[:en]Read more📽 New video!!

Watch our impressive movie about our ‘𝘀𝘁𝗮𝘁𝗲 𝗼𝗳 𝘁𝗵𝗲 𝗮𝗿𝘁 𝗰𝗼𝗮𝘁𝗶𝗻𝗴 𝗲𝗾𝘂𝗶𝗽𝗺𝗲𝗻𝘁’ and the team behind it!

[:nl]Lees verder[:en]Read moreIRCD Coating Plant at Technisem France

𝗪𝗼𝗿𝗸 𝗶𝗻 𝗽𝗿𝗼𝗴𝗿𝗲𝘀𝘀! Currently our team is assembling and commissioning an impressive 𝗜𝗥𝗖𝗗 𝗖𝗼𝗮𝘁𝗶𝗻𝗴 𝗣𝗹𝗮𝗻𝘁 at TECHNISEM in France (IRCD = Integrated Rotary Coating & Drying) We thank Technisem for the trust and pleasant cooperation.

[:nl]Lees verder[:en]Read moreThank you – Bejo Zaden

As a thank you for the wonderful assignment from Bejo Zaden, a photo of the new 𝗛𝗶𝗴𝗵-𝗧𝗲𝗰𝗵 𝗙𝗶𝗹𝗺 𝗖𝗼𝗮𝘁 𝗶𝗻𝘀𝘁𝗮𝗹𝗹𝗮𝘁𝗶𝗼𝗻 is handed over to Geert Dekker, Coating & Pelleting Team Leader. Another perpetuation of our great collaboration!

[:nl]Lees verder[:en]Read moreEnza Zaden Germany is now the proud owner of a VCS600-3 Vibrating Calibration System

Because they work with special seeds, the sieving parts needed to be manufactured in Stainless Steel. What a great result and happy customer!

[:nl]Lees verder[:en]Read moreWork in Progress – BioRinse

Our engineers and technicians are currently testing and fine-tuning an impressive 𝗕𝗶𝗼𝗥𝗶𝗻𝘀𝗲 treatment station. See www.hoopman-equipment/news

[:nl]Lees verder[:en]Read moreBio coating lines for Bejo

In order to visually distinguish organic seed and non-chemically treated seed, Bejo has opted for an improved new yellowish colour coating for the organic seed. This new durable coating consists of natural materials that break down completely. The coating also has a shorter drying time, which benefits the vitality of the seed and saves energy. Read More

[:nl]Lees verder[:en]Read moreHoopman e&e now also on Facebook!

[:nl]Lees verder[:en]Read moreTestimonial – VCS400

March 17th 2021 With great pleasure (and pride) we received these kind words from a highly valued customer:

[:nl]Lees verder[:en]Read moreCorona measures

Given the recent developments and decisions regarding the COVID-19 virus, we at Hoopman equipment & engineering also take our social responsibility to avoid personal contact as much as possible. Despite the Corona virus, our company remains open, but additional measures have been introduced to minimize the chance of spreading: As many office workers as possible Read More

[:nl]Lees verder[:en]Read moreTurn-Key Projecten

The last year we have delivered and build several projects world-wide. Below a small impression on what we have done. Beside deliverying individual equipment we are specialized in turn-key projects. From the engineering phase up to delivering, assembling comissioning and training! Want to know more? Then contact our sales team! Seed Cleaning plant in Limburg Read More

[:nl]Lees verder[:en]Read more