The disinfection of seeds for agriculture and horticulture is important to grow good plants, either at the plant raiser’s greenhouse or in the field. Due to the drastic limitation of registered seed applied fungicides alternatives have to be available.

Because of the unique hot- or bleach- water- treatment, the pathogens in/on the seeds will be targeted while limiting any negative effects on the germination of the seeds. In this way, compared with the current (chemical) disinfection method, the hotwatertreatment brings a number of benefits. This includes quality gains, energy saving, less emission of harmfull substances, reduction of waste gases and a faster process.

Besides that, the possibly excess treated seed doesn’t need to be drained as chemical waste.The BioRinse method is especially focused on the efficient running of long known hot- or bleach water treatment. The implementation of the BioRinse-installation ensures that each seed undergoes an identical Heat/Rinsing/Drying protocol.

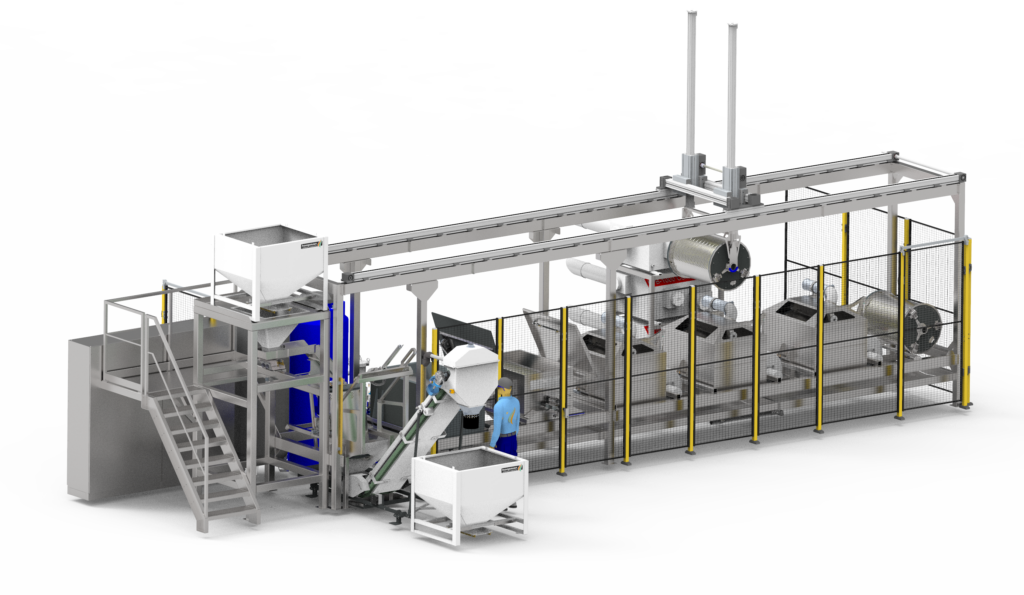

A steam based disinfection system was developed based on basic research done by TNO and further significally changed and refined during a regional government GoEfro r&d project, resulting in the current BioFlash line.

Both systems work of dry seed to dry seed; this also gives many logistic and quality benefits.

Priming effect: not only in BioRinse but also in the BioFlashprocess also germ-accelerating effects emerged. This makes sense because the superheated steam has a controllable abrasive effect on the seed skin; the dried back seed will faster absorb water at germination. Water-absorption is the principal start of germination.

So for ‘physical’ disinfection, Hoopman has developed 2 new machines: the BioRinse and the BioFlash.